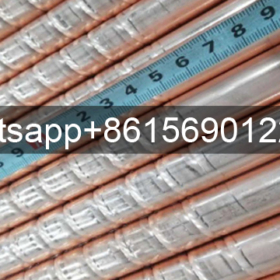

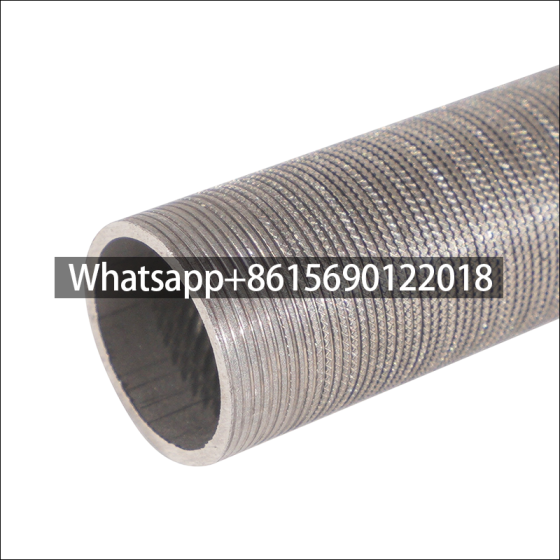

The Copper, Cupro Nickel Corrugated Fin Tube Heat Exchanger Tube is a high-efficiency heat exchanger tube, its core strength lying in its material and corrugated fin design.

Materialeigenschaften: Copper and Cupro Nickel alloys are common choices. Copper has excellent thermal conductivity, while Cupro Nickel alloys offer superior corrosion resistance, making them particularly suitable for harsh environments such as seawater.

Corrugated Fin Design: This structure significantly improves heat exchange efficiency by increasing surface area, making it ideal for air-to-fluid heat exchange.

Applications: This type of heat exchanger tube is widely used in boilers, HVAC systems, industrial heat exchangers, and refrigeration equipment for efficient heat transfer.

Functions of Corrugated Fin Tube:

1. In boiler applications, after heat exchange and flow resistance optimization, the heat transfer capacity of one threaded flue tube is equivalent to 1.7-1.8 ordinary flue tubes of the same size. This not only significantly reduces the number of flue pipes but also allows for a smaller boiler shell diameter, thus significantly reducing steel consumption in pressure-bearing components, saving steel, and lowering costs.

2. In the air conditioning and refrigeration industry, compared to ordinary smooth tubes, the heat transfer surface area exceeds that of smooth tubes by 1.5-2.0 Mm, greatly improving refrigerant flow and enhancing the boiling and condensation heat exchange effects within the tube. The refrigerant is propelled in a spiral shape through the internal threads, reducing pressure loss by more than 50%. Manufacturing requires the same processing techniques as ordinary tubes, such as tube expansion and welding. This allows for smaller and lighter air conditioners, saving about one-third of the tube weight compared to smooth tubes. It also saves electricity and reduces costs.

3. In heat exchange equipment, steel or stainless steel tubes are formed in one piece by machine tool rolling. The scale on the surface of the spiral tube is spiral-shaped. Temperature changes during equipment operation cause the tube to expand and contract, allowing the scale to detach on its own; while the scale on smooth tubes is cylindrical and has no self-removal force. It is now widely used in power plant condensers and boiler auxiliary heat exchange systems, and is one of the alternatives to bare tubes and copper tubes.

dtfinnedtube.com

dtfinnedtube.com