Introduction to Threaded Low Fin Tubes

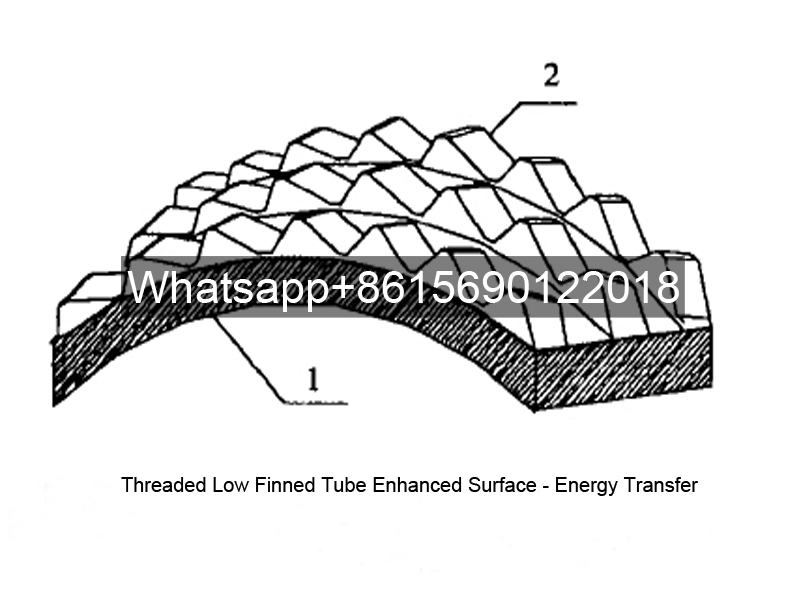

Threaded low fin tubes are a high-efficiency heat exchange element consisting of a tube base and three-dimensional diamond-shaped circumferential fins. The diamond-shaped fins are attached to the outer surface of the tube base at a specific helix angle. The diamond-shaped fins are trapezoidal in shape, with triangular notches between them. The notches appear periodically along the circumference of the fins, and adjacent circumferential fins maintain a fin spacing.

Enhanced Finned Tubes-Threaded Low Fin Tube

The basic principle of threaded low fin tubes in enhancing condensation or convective heat transfer is that when steam condenses on the diamond-shaped fin surface, the surface tension of the condensate film and the changing radius of curvature of the diamond-shaped fin surface cause the condensate film to condense at the fin base. The condensate film on the fins is very thin, thus enhancing condensation heat transfer. The principle, characteristics, and application range of hollow ring-supported diamond fin tube heat exchangers are also detailed.

Threaded Low-Fin Tubes: Enhanced Surface – Energy Transfer

Heat transfer tubes utilize three-dimensional fins to enhance condensation or convection heat transfer. Among these new types of enhanced heat transfer tubes, threaded fin tubes and petal-shaped fin tubes are currently the most widely used in industry, primarily in the power, Kühlung, and chemical industries.

Threaded Low-Fin Tubes Enhanced Surface – Energy Transfer

Threaded low-fin tubes are made of both hard steel and soft copper (or aluminum). Their disadvantage is that they enhance heat transfer by increasing the heat transfer area, but do not improve the heat transfer film coefficient (calculated based on the actual surface area) during condensation or convection. Furthermore, when the finning ratio is high, the heat transfer film coefficient calculated based on the actual surface area is even lower than that of ordinary smooth tubes, failing to fully utilize the heat transfer enhancement effect of the effective heat transfer area.

The circumferential, non-continuous, three-dimensional fins of petal-shaped finned tubes can improve the heat transfer film coefficient (calculated based on actual area) during both condensation and convective heat transfer. This maximizes the heat transfer enhancement effect of the effective heat transfer area and offers superior heat transfer enhancement performance compared to threaded finned tubes. However, petal-shaped finned tubes are currently only available in soft copper (or aluminum) metals, which are relatively expensive and hinder their widespread adoption in industrial applications.

In oil refining and petrochemical production, where heat transfer loads are high, only relatively low-cost heat transfer tubes are suitable for widespread use. Diamond-shaped finned tubes are a newly developed type of steel three-dimensional finned tube with low processing costs and excellent heat transfer performance.

Using diesel as the working medium, two comparative tests were conducted to investigate the heat transfer enhancement characteristics of diamond-shaped finned tubes in oil coolers and oil condensers, respectively.

Structure of a Threaded Low-Finned Tube

A threaded low-finned tube primarily consists of a tube base and diamond-shaped, three-dimensional circumferential fins. Diamond-shaped, three-dimensional circumferential fins are attached to the outer surface of the tube base at a specific helix angle. The diamond-shaped fins are trapezoidal in shape, with triangular notches between them. These notches appear periodically along the circumference of the fins, maintaining a fin spacing between adjacent circumferential fins.

Threaded Low Finned Tubes Manufacturer and Supplier

Mechanism of Heat Transfer Enhancement in Threaded Low-Fin Tubes

Basic Principle of Threaded Low-Fin Tubes for Enhancing Condensation or Convection Heat Transfer

When steam condenses on the diamond-shaped fin surface, the surface tension of the condensate film and the varying radius of curvature of the diamond-shaped fin surface cause the condensate film to condense at the fin base. The condensate film on the fins is very thin, enhancing condensation heat transfer.

When fluid flows transversely (or longitudinally) over the diamond-shaped fin surface, the fluid heat transfer boundary layer is periodically disrupted at the discontinuous circumferential fins, reducing the thickness of the fluid heat transfer boundary layer and improving the convective heat transfer film coefficient.

Enhanced Heat Transfer Characteristics of Threaded Low-Finned Tubes in Oil Coolers

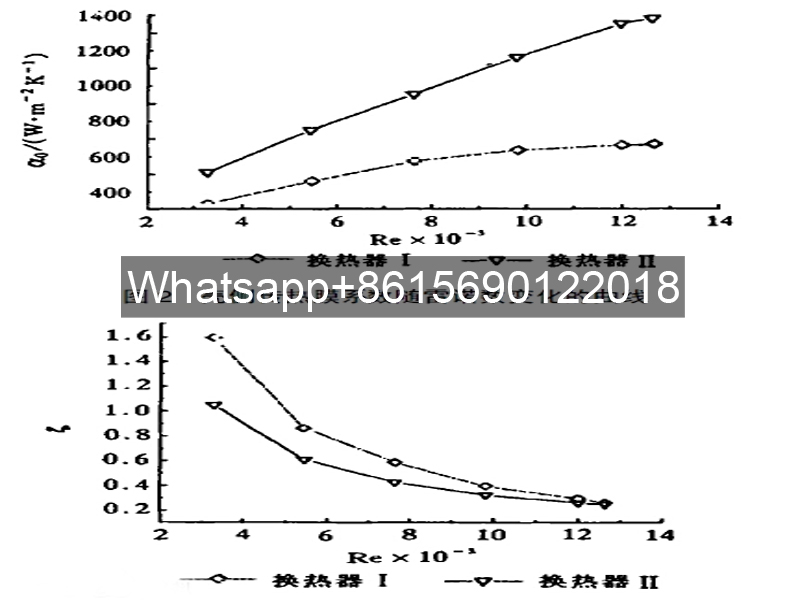

Using diesel as the working fluid, two heat exchangers with different tube bundles were tested to investigate the enhanced heat transfer and flow resistance performance of diamond-finned tubes. Both heat exchangers used spiral baffles as the shell-side support structure. Heat exchanger 1 contained a smooth tube bundle, while heat exchanger 2 (the oil cooler) contained a threaded low-finned tube bundle.

Enhanced Heat Transfer Characteristics of Threaded Low-Finned Tubes in Oil Coolers

Heat exchangers 1 und 2 were connected in series. Diesel, approximately 40°C, was heated to approximately 80°C in the shell side of heat exchanger 3 by steam flowing through the tube side. It then entered the shell side of heat exchanger 1 and was cooled to approximately 40°C by cooling water flowing through the tube side. The diesel flow rate was varied, and the diesel inlet and outlet temperatures, steam inlet and outlet temperatures, cooling water inlet and outlet temperatures and flow rates, and the shell-side inlet and outlet pressure gauge readings of heat exchanger 1 and heat exchanger 2 were recorded at different flow rates.

After obtaining the total heat transfer coefficient of the heat exchanger, the shell-side heat transfer film coefficient of the heat exchanger was calculated. The shell-side flow resistance coefficient was calculated based on the flow path analysis results of the fluid on the shell side of the spiral baffle heat exchanger.

As the Reynolds number increases, the shell-side heat transfer film coefficient of both the heat exchanger and the heat exchanger increases due to increased turbulence. At the same Reynolds number, the shell-side heat transfer film coefficient of the heat exchanger is 54% to 108% higher than that of the heat exchanger. The increase in the heat transfer film coefficient increases with increasing Re.

As the Reynolds number increases, the resistance coefficient of diesel flowing through the heat exchanger and the shell side of the heat exchanger decreases. At the same Reynolds number, due to the greater leakage rate of the three-dimensional fins through the baffle pores, the resistance coefficient of diesel flowing through the shell side of the heat exchanger is 30% to 5% lower than that of the heat exchanger.

As the Reynolds number increases, the turbulence caused by the three-dimensional fin disturbance intensifies, and the resistance coefficient on the shell side of the heat exchanger gradually approaches the resistance coefficient of the heat exchanger. It is predicted that as the Reynolds number increases further, the flow resistance coefficient on the shell side of the heat exchanger will exceed the resistance coefficient of the heat exchanger.

The three-dimensional fins of the threaded low-fin tube can improve the heat transfer film coefficient on the shell side of the heat exchanger, effectively enhancing convective heat transfer.

Principle of the Threaded Low-Fin Tube Heat Exchanger

The threaded low-fin tube heat exchanger is a new type of high-efficiency heat exchanger that uses diamond-shaped fin tubes as heat transfer elements and a hollow ring support structure for the baffles.

The threaded low-fin tubes in this heat exchanger are high-efficiency heat transfer tubes with circumferentially discontinuous three-dimensional fins, and their heat transfer enhancement performance is superior to that of threaded fin tubes with circumferentially continuous fins.

When used for condensation heat transfer enhancement, the unique three-dimensional fin structure creates a non-uniform surface tension distribution on the liquid film on the fin surface—higher at the base and lower at the top. This pulls the liquid film toward the base, significantly reducing the film thickness on the three-dimensional fin surface, lowering thermal resistance and enhancing the heat transfer capacity between the vapor medium and the outer tube wall, thereby improving heat transfer efficiency.

When used for convection heat transfer enhancement, the discontinuous nature of the fins periodically disrupts the fluid’s heat transfer boundary layer, effectively thinning the heat transfer boundary layer on the fin surface, reducing the heat transfer resistance at the bottom layer of the boundary stagnation, and improving heat transfer efficiency. Furthermore, the baffles of this heat exchanger can utilize hollow rings as support elements.

The hollow ring tube support system transforms the support plate’s tube bridge into a flow channel for the shell-side medium, transforming conventional transverse flow into longitudinal flow. This flow method minimizes the fluid’s bulk resistance, allowing the majority of the fluid’s pressure drop to act on the rough heat transfer interface of the heat-transfer enhancement tubes, promoting convective heat transfer at that interface. This fully utilizes the heat transfer enhancement properties of the enhancement tubes and effectively avoids the adverse effects of various shell-side supports on the fluid’s bulk resistance, achieving high heat transfer performance under low flow resistance conditions.

Features of Threaded Low-Fin Tube Heat Exchangers

1. Im Vergleich zu glatten Rohren, the surface film heat transfer coefficient or convective film heat transfer coefficient is increased by 1-3 times;

2. Using hollow rings as support significantly reduces shell-side flow resistance;

3. The cost is generally comparable to that of a bare tube heat exchanger for the same heat load. Especially during expansion and renovation, a 20-30% increase in processing capacity can often be met simply by replacing the tube bundle, without requiring modifications to the equipment foundation or piping.

4. Eliminates dead zones caused by lateral deflections, reduces fouling, and increases service life.

5. The longitudinal flow of the shell-side medium reduces tube vibration, effectively minimizing premature damage to heat exchangers caused by tube bundle vibration.

Applications of Threaded Low-Fin Tube Heat Exchangers

Made of carbon steel, threaded low-fin tubes can be widely used in various liquid-liquid, gas-liquid, and gas-gas heat exchangers in the petroleum, chemical, and power industries, with condensing phase change or convection heat transfer as the primary method. As long as the shell-side medium is relatively clean and free of solid particles and colloids, diamond-shaped fin heat exchangers can be used, or threaded low-fin tube heat exchangers can be used to replace bare tube heat exchangers to improve heat transfer efficiency.

As long as the operating requirements of threaded low-fin tubes are met, conventional heat exchangers of all specifications and types can use threaded low-fin tubes as heat exchange elements, with hollow ring support plates as support components, to create high-efficiency threaded low-fin tube heat exchangers.

The three-dimensional fins of threaded low-fin tubes significantly enhance both convective heat transfer within oil coolers and condensation heat transfer within oil condensers.

Threaded low-fin tubes address the problem of existing steel circumferentially continuous finned tubes (such as threaded finned tubes), which suffer from poor fin heat transfer enhancement and fail to fully utilize the effective heat transfer area. They also overcome the drawbacks of copper (or aluminum) circumferentially discontinuous finned tubes (such as petal-shaped finned tubes), which suffer from the high cost of metal and significant limitations in industrial applications, hindering widespread adoption. Their application in the petrochemical industry promises significant energy savings and consumption reduction.

dtfinnedtube.com

dtfinnedtube.com