Steel spiral-finned tubes are manufactured using a direct winding process. This involves mechanically wrapping a high-quality steel strip tightly and evenly around the outer surface of a high-quality seamless steel tube using a dedicated winding machine. The ends are then spot-welded to secure the tube. The entire tube is then hot-dip galvanized.

Steel Spiral Finned Tube-Steel Fin Tube Manufacturer and Supplier

Features of Steel Spiral-Finned Tubes

1. The fins are tightly wrapped around the outer surface of the tube. Thermal laboratory testing has shown low contact thermal resistance and high heat transfer performance.

2. Durability: In rural environments, a standard hot-dip galvanizing layer can maintain its rust protection for over 50 years without repair. In urban or coastal areas, it can last up to 20 years without repair.

3. Reliability: The zinc coating is metallurgically bonded to the steel and becomes part of the steel surface, ensuring a durable and reliable coating.

4. Toughness: The zinc coating forms a unique metallurgical structure that withstands mechanical damage during transportation and use.

5. Comprehensive Protection: Every part of the component is zinc-coated, ensuring comprehensive protection even in recessed areas, sharp corners, and hidden areas.

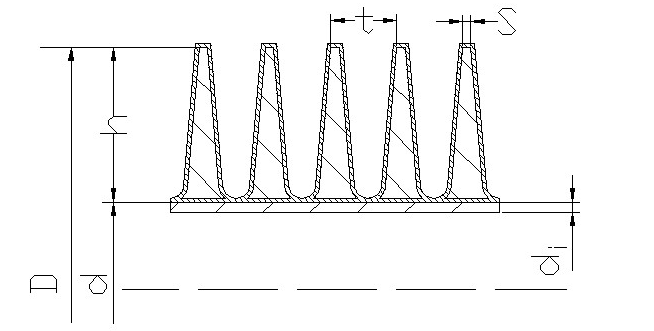

Steel Spiral Fin Tube Structure Diagram

D = fin tube outer diameter; di = base tube wall thickness; t = fin pitch; d = fin tube root diameter; S = fin thickness; h = fin height.

dtfinnedtube.com

dtfinnedtube.com