Serrated finned tubes, as a highly efficient and stable heat exchange technology, play a vital role in modern industry.

What are serrated finned tubes?

As the name suggests, serrated finned tubes feature serrated fins. They consist primarily of a base tube and fins, which are attached to the base tube in a specific pattern, forming a unique heat exchange element.

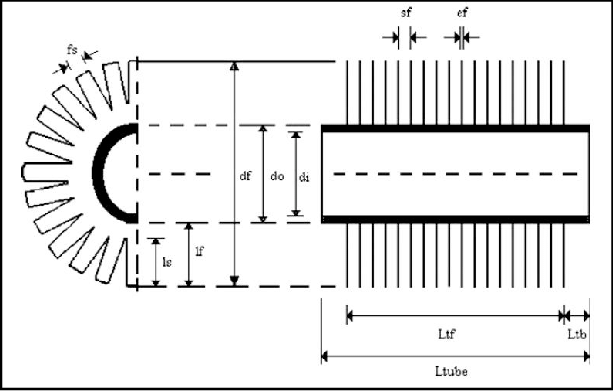

Serrated Finned Tube Drawing from Cangzhou Datang Steel Pipe Co., Ltd

Features of Serrated Finned Tubes

Serrated finned tubes are distinguished by the absence of any gaps between the fins and the tube wall, significantly increasing the heat dissipation area and improving heat exchange efficiency. Data shows that the heat dissipation area of serrated finned tubes can reach over 95% of the total fin area, laying a solid foundation for their application in high-efficiency heat exchange.

Serrated Finned Tube Structure

Fin Design: The fin design of serrated finned tubes is a hallmark of their uniqueness. The serrated fins not only increase the contact area between the fins and the fluid, but also create vortices during fluid flow, thereby enhancing heat exchange. The tooth-like structure also effectively prevents clogging and dust accumulation between the fins, ensuring long-term, stable operation of the heat exchanger.

Material Selection: Serrated fin tubes are typically made of aluminum alloy, copper alloy, carbon steel, and other materials. These materials offer excellent thermal conductivity, corrosion resistance, and mechanical strength, meeting the heat exchange requirements of various operating conditions.

Connection Methods: Serrated fin tubes can be connected to the base tube in two main ways: fish-scale connection and center-tube connection. The fish-scale connection involves inserting one end of the fin into a fish-scale groove with one end of the tube, creating a relatively fixed connection. The center-tube connection, on the other hand, involves drilling holes in the fins and directly welding them to the tube. Both connection methods have their advantages and disadvantages, and users can choose the right one based on their specific needs.

Working Principle of Serrated Fin Tubes

Serrated fin tubes operate by directing fluid into the tube and transferring heat through heat exchange between the tube and fins. During this process, heat is transferred from the fluid to the tube and then to the air through radiation from the fins and convection. Due to their large heat dissipation area and efficient heat transfer performance, serrated fin tubes enable fast and stable heat exchange.

Applications of Serrated Fin Tubes

Serrated fin tubes, with their efficient and stable heat exchange performance, are widely used in the chemical, petroleum, and pharmaceutical industries. They are primarily used for heat exchange with high-temperature, high-pressure, and highly corrosive media such as steam, hot water, cold water, refrigerants, solvents, and brine. Compared to conventional heat exchangers, serrated fin tubes offer advantages such as high heat transfer efficiency, low resistance, excellent impact resistance, light weight, and compact structure, leading to their widespread application.

Datang Fin Tube Technical Parameters

| PRODUCT | TYPE | TUBE MATERIAL | FIN MATERIAL | TUBE SIZE | FIN SIZE |

| Heat Exchanger Finned Tube | Extruded Fin Tube | All Kind of Material can be applied | Aluminum A1100 | 15.88~50.8 | 7~11.5FPI |

| Fin Height Max 16mmH | |||||

| L-Foot Fin Tube | All Kind of Material can be applied | Copper C1100, C1220 | 12.70~50.8 | 7~11.5FPI | |

| (Wrap On Type) | Fin Height Max 16mmH | ||||

| G-Fin Tube (Embedded Type) | Aluminum A1100, A1050, A1060 | ||||

| High Frequency Welded Finned Tube | A179 Carbon Steel Tube | Carbon Steel Tube | 12.70~160 | 1.5~7FPI | |

| Stainless Steel Tube | Stainless Steel Tube | 0.8~3.2mm. Thickness | |||

| Alloy Steel Material | Alloy Steel Material | ||||

| Integral Copper & Copper Alloy High Finned Tube | C12200, C11000, C70600 | C12200, C11000, C70600 | 15.88~22.23 | 5~9FPI | |

| Max 12mm. H | |||||

| Oval Finned Tube | Carbon Steel Tube | Carbon Steel Tube | All Size Available | 5~15FPI | |

| Stainless Steel Tube | Stainless Steel Tube | ||||

| Alloy Steel Material | Alloy Steel Material | ||||

| Copper & Copper Alloy Tube | Copper & Copper Alloy Tube | ||||

| Monometallic Fin Tube | Low Fin Tube | Carbon Steel, stainless steel, titanium, copper, brass, nickel alloy, etc. | — | 9.52~40 | 12, 16, 19 28 FPI, etc. |

| Turbo-C Tube | |||||

| Turbo-E Tube | |||||

| Corrugated Tube | All Kind of Material | — | 6.35~40 | 2~9FPI |

Fin Tube Packaging