The air cooler uses forced ventilation to exchange heat between the hot fluid in the tube and the air outside the tube to achieve cooling or condensation. Its core working principle is as follows:

Working principle of air cooler

The high-temperature fluid flows in the tube and exchanges heat with the air outside the tube through the tube wall and fins. The fan forces ventilation to accelerate the air flow to improve the heat exchange efficiency. When the air passes over the fins, the heat is transferred from the fluid to the air, thereby reducing the fluid temperature.

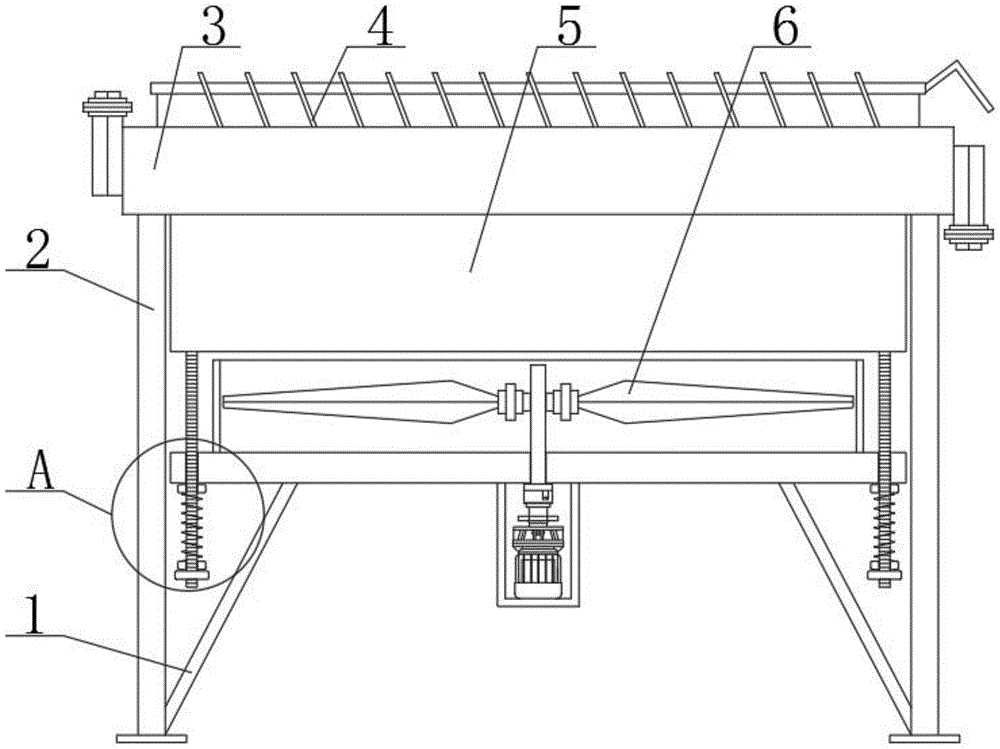

Structural composition of air cooler

It is mainly composed of tube bundles, brackets and fans. The tube bundle usually uses aluminum finned tubes to enhance the heat transfer effect; the bracket is used to fix the tube bundle and support the structure; the fan forces air through axial flow or centrifugal flow to enhance the heat exchange process.

Cooling method of air cooler

Dry air cooling: It only relies on fan air supply for cooling, with a simple structure but low efficiency.

Wet air cooling: It enhances heat exchange by spraying or atomizing water, but it is easy to cause equipment corrosion and is less used.

Here is the professional of the air cooler (Air cooled heat exchanger) working principles and operational mechanisms, based on authoritative technical sources:

? I. Core Working Principles

-

Heat Exchange Mechanism

Hot fluids (water/oil/steam) flow through sealed tube bundles while axial fans drive air across external finned surfaces. Heat transfers through tube walls to fins and is dissipated via forced convection. -

Temperature Gradient Drive

- Forced Convection Type: Fans generate directional airflow for cooling high-temperature media (>60°C).

- Natural Convection Type: Relies on air density differences for self-circulation (no fan), energy-saving but less efficient (requires >15°C temperature difference).

-

Phase-Change Assisted Cooling (Wet Air Coolers)

Spray systems atomize water onto finned tubes; water film evaporation absorbs significant heat, dramatically enhancing efficiency—ideal for near wet-bulb temperature scenarios.

⚙️ II. Key Structural Components

-

Heat Transfer Core: Finned Tube Bundles

- Materials: Aluminum/copper fins (thermal conductivity >4000 W/(m·K)) bonded to steel tubes, expanding surface area by >30%.

- Types:

- L-Type Fins: ≤150°C, general purpose;

- LL-Type Fins: ≤170°C, corrosion-resistant;

- G-Type Embedded: High-pressure applications.

-

Ventilation System

- Fan Types:

- Forced Draft: Fans below tubes push air upward (simple structure);

- Induced Draft: Fans above tubes pull air downward (reduces hot air recirculation, quieter).

- Louvers: Regulate airflow and prevent freezing in winter.

- Fan Types:

-

Tube Headers & Frames

- Headers: Distribute fluid to branch tubes; fixed ends withstand pressure while free ends accommodate thermal expansion;

- Frames: Support tube bundles and fans, ensuring airtightness and vibration resistance.

? III. Operational Process (Forced-Draft Dry Air Cooler Example)

- Hot Fluid Input: Medium enters inlet headers and distributes evenly into finned tubes;

- Air Forced Convection: Axial fans drive air transversely across tubes, absorbing heat;

- Heat Dissipation: Warmed air exhausts through top louvers;

- Cooled Medium Output: Chilled fluid collects in outlet headers for discharge.

⚡ IV. Enhanced Heat Transfer Technologies

- Fin Optimization: Corrugated/serrated fins increase airflow turbulence, boosting heat transfer coefficients;

- Spray Humidification (Wet Type): Precools air toward wet-bulb temperature, improving temperature differential utilization by 40%;

- Variable Frequency Control: Adjusts fan speed based on load, reducing partial-load energy use by >20%.

⚖️ V. Application Scenarios & Limitations

| Scenario | Advantages | Limitations |

|---|---|---|

| Arid Regions | 100% water-free operation915 | Lower efficiency than water cooling (requires >15°C ΔT) |

| High-Temp Industrial Media | Withstands >150°C, pressure >16 bar56 | Efficiency drops sharply at ambient >38°C |

| Power/Chemical Condensation | Zero water pollution, low maintenance (~2% CAPEX/year)1013 | Higher initial cost vs. water cooling |

Conclusion: Air coolers achieve cooling through air-finned tube forced heat exchange, excelling in water conservation and harsh-environment adaptability. Efficiency remains limited by ambient temperature differentials. Selection requires holistic analysis of medium properties, climate, and cost.

dtfinnedtube.com

dtfinnedtube.com