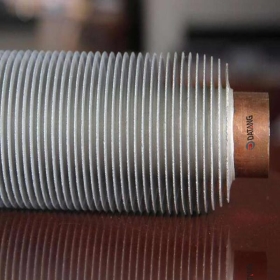

Copper-Aluminum Composite Finned Tubes: Technology and Applications

What is Copper Tube Aluminum Fin Composited Extruded Fin Tube?

Copper-aluminum composite extruded finned tubes are high-efficiency heat transfer components consisting of a copper inner tube mechanically bonded to aluminum fins through an extrusion process. This bimetallic design combines the superior thermal conductivity of copper (385 W/m·K) with the lightweight and cost-effectiveness of aluminum (237 W/m·K), achieving optimal performance in heat exchange systems.

Copper Tube Aluminum Fin Composited Extruded Fin Tube 제조공정

- Tube Preparation: Oxygen-free copper tubes are cleaned and degreased.

- Fin Formation: Aluminum sleeves are hydraulically extruded onto the copper tube at 350-450°C, creating seamless fins with 0.3-1.5mm thickness.

- Bonding: The extrusion process generates a metallurgical bond at the Cu-Al interface with contact pressure >20MPa.

- Finishing: CNC machining ensures fin pitch accuracy (±0.1mm) and surface oxidation treatment enhances corrosion resistance.

How does Copper Tube Aluminum Fin Composited Extruded Fin Tube work?

Heat transfers from the internal fluid (예), refrigerant) through the copper tube wall to the aluminum fins via conduction. The fin geometry (typically 8-16 fins/inch) maximizes surface area, while turbulent airflow between fins enhances convective heat transfer. The thermal contact resistance at the Cu-Al interface is minimized to <0.01 m²·K/W through the extrusion bond.

What are the advantages of Copper Tube Aluminum Fin Composited Extruded Fin Tube?

- Thermal Efficiency: 15-30% higher heat transfer coefficient than monolithic tubes.

- 내식성: Aluminum fins protect copper from external corrosion in harsh environments.

- Weight Reduction: 40% lighter than all-copper designs.

- Cost-Effectiveness: Aluminum replaces 60-70% of copper material volume.

Copper Tube Aluminum Fin Composited Extruded Fin Tube Application Cases

- HVAC Systems: Used in 80% of modern air-cooled chillers, reducing energy consumption by 12% (Carrier Corp case study).

- Power Plants: Deployed in condenser tubes at Guangdong LNG Terminal, withstanding salt spray while maintaining 92% efficiency over 5 년.

- Automotive: Tesla’s battery thermal management system uses micro-finned variants (0.8mm pitch) for compact heat dissipation.

Figure 1. Cross-section of extruded finned tube showing Cu-Al diffusion layer (SEM image).

dtfinnedtube.com

dtfinnedtube.com