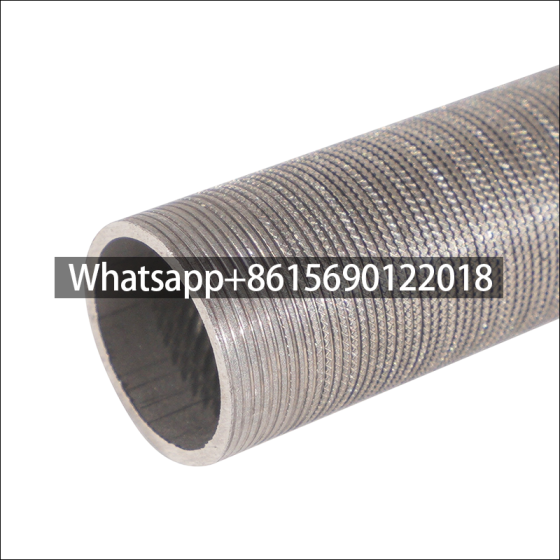

What Is Enhanced Evaporation Tube?

Enhanced evaporation tube refers to a tube design that increases the heat transfer area or improves the heat transfer performance during the evaporation process. This design is aimed at enhancing the heat transfer efficiency during the evaporation process. Typically, methods such as surface treatment, material improvement, and structural optimization are employed to achieve the design of enhanced evaporation tubes.

Enhanced Evaporation Tube Principle

This innovative heat exchange tube is designed to induce vigorous vaporization boiling on its outer surface. Its exceptional heat conduction capabilities stem from a unique pore structure. The optimization of the micro pore structure goes beyond merely increasing the heat exchange area; it enhances the evaporation core, facilitating the efficient removal of impurities and reducing fouling. 이, 차례대로, minimizes external heat resistance, leading to a significant improvement in the thermal efficiency of the tube exchange. The inner surface of the tube features spiral grooves to further augment the heat transfer area and turbulence effect, thereby reducing heat resistance within the tube.

The enhanced internal and external heat transfer efficiency substantially enhances the comprehensive heat transfer capacity of the tube. This allows for a proportional reduction in the volume and weight of the heat exchanger, aligning with energy-saving and cost-reduction objectives.

Enhanced Evaporation Tube Material And Size

| Executive Standards | Compliant with GB/T19447 or equivalent to ASTM B359, ASME SB 359. | |

| Materials | Available in red copper T2/TP2, iron white copper BFe10-1-1, complex brass HSn70-1, HAl77-2, C12200, C44300, C68700, C70600, C71500 etc. | |

| Status | Wing clip H02, smooth segment O60, or whole O60. | |

| Specifications | Outer Diameter (Do) | Φ15.88~Φ25.4mm |

| Thickness (To) | 1.0-1.5밀리미터 | |

| 핀 높이 (Hf1) | ≤1.70mm | |

| Fins Per Inch (증권 시세 표시기) | 40-56 wing/inch | |

| Fins Per Inch (증권 시세 표시기) | ≤5m | |

| Packing | Securely packed in wooden cases. | |

The enhanced evaporation tube finds primary application in centrifugal chillers, water chillers, and shell-and-tube heat exchangers operating within small temperature differentials.

These types of tubes are commonly applied in heat exchange equipment such as evaporators, condensers, and heat exchangers. In industries such as chemical engineering, power generation, 냉각, and air conditioning, enhanced evaporating tubes are widely used to enhance the efficiency of energy transfer.

Main types and features of enhanced evaporator tubes

Spiral groove tube : Through the flow restriction effect and body resistance near the spiral groove wall, the fluid in the tube produces local secondary flow, enhancing the heat transfer effect. Suitable for convection, boiling and condensation conditions, with high anti-fouling and heat transfer performance.

Horizontal groove tube : When the fluid in the tube flows through the transverse ring ribs, an axial vortex is formed, which increases the boundary layer disturbance and promotes heat transfer. This design helps to maintain a stable enhancement effect.

Convergence tube : The surface has a bamboo-like structure, which causes the medium to produce a contraction and amplification effect when it flows, increases the degree of turbulence, and improves the heat exchange capacity. The sudden change of fluid direction and speed at the tube wall forms local turbulence and reduces thermal resistance.

Low thread fin tube : The outer surface is rolled to form threaded fins, which increases the heat exchange area and divides the laminar boundary layer, reduces thermal resistance, and improves the boiling and condensation heat transfer efficiency.

Spiral flat tube : The unique structure makes the tube side and the shell side in spiral flow at the same time, promoting turbulence and enhancing heat transfer effect.

Application scenarios and advantages of enhanced evaporator tubes

Enhanced evaporator tubes are widely used in various industrial processes that require efficient heat transfer, such as chemical, pharmaceutical, food processing, 등.

Its advantages include:

Efficient heat transfer : Through special structural design, the heat transfer effect of the fluid inside and outside the tube is enhanced to improve the evaporation efficiency.

Strong anti-fouling performance : Certain designs such as spiral grooved tubes can effectively resist dirt accumulation and maintain long-term efficient operation.

Wide range of applications : Applicable to various working conditions such as convection, boiling and condensation to meet different application requirements.

dtfinnedtube.com

dtfinnedtube.com