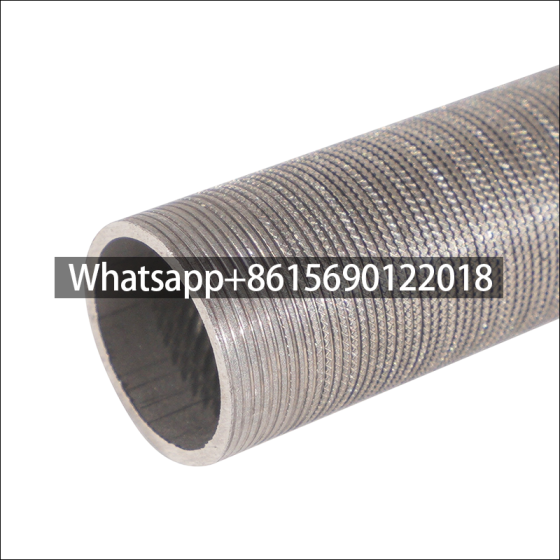

Enhanced Heat Transfer Performance of Grooved Integral Low-Fin Tubes

Integral low-fin tubes with grooved channels (commonly called “grooved tubes”) represent an advanced heat transfer enhancement technology that combines the benefits of extended surfaces and turbulence promotion. This article examines their thermal-hydraulic characteristics, 제조 공정, and industrial applications.

1. Grooved Integral Low Finned Tube Introduction

Grooved integral low-fin tubes feature:

- Base tube diameter: 12.7-25.4 밀리미터 (standard sizes)

- Fin height: 0.5-1.5 밀리미터 (typically 20-30% of tube diameter)

- Fin density: 40-60 fins per inch (증권 시세 표시기)

- Spiral grooves: 10-30° helix angle with 0.2-0.5 mm depth

The unique design creates three heat transfer enhancement mechanisms simultaneously:

- Surface area expansion (150-300% increase)

- Boundary layer disruption via grooves

- Secondary flow generation

2.Grooved Integral Low Finned Tube Thermal Performance

Experimental data shows:

- Heat transfer coefficients 2-4× higher than smooth tubes

- Optimal performance at Reynolds numbers 3,000-15,000

- Groove depth/width ratio of 0.3-0.5 provides best efficiency

- Typical fin effectiveness: 0.7-0.9

The grooves create swirling flows that:

- Reduce thermal boundary layer thickness

- Promote fluid mixing between fin channels

- Maintain performance during partial fouling conditions

3. Grooved Tubes Integral Low Finned Tube Manufacturing Methods

Primary production techniques:

- Cold rolling: Most common for copper/copper alloys

- Skiving: Preferred for stainless steel applications

- Extrusion: Used for aluminum tubes

Quality control parameters:

- Fin height tolerance: ±0.05 mm

- Groove dimensional accuracy: ±0.02 mm

- Surface roughness: Ra < 0.8 μm

4. Grooved Tubes Integral Low Finned Tube Applications

Widely used in:

- Shell-and-tube heat exchangers

- Refrigeration evaporators/condensers

- Power plant condensers

- Petrochemical process equipment

Case study: A methanol plant achieved 22% energy savings by replacing smooth tubes with grooved low-fin tubes in their feedwater heaters.

5. Grooved Tubes Integral Low Finned Tube Future Developments

Emerging trends include:

- Hybrid surfaces combining grooves with porous coatings

- Additive manufacturing for customized geometries

- Nano-engineered surface treatments

- Smart materials with adaptive fin configurations

결론

Grooved integral low fin tubes offer superior thermal performance while maintaining reasonable pressure drop characteristics. Their robust construction and fouling resistance make them particularly suitable for industrial heat exchangers operating under challenging conditions.

dtfinnedtube.com

dtfinnedtube.com