열교환기용 L형 핀 튜브

Datang의 알루미늄 L 형 핀 튜브 튜브 둘레에 나선형으로 단단히 감긴 얇은 알루미늄 핀 스트립으로 구성. L자형 다리, 1/16" 와이드, 핀 스트립의 한쪽 면에 먼저 형성됩니다. (따라서 L-Foot이라는 이름이 붙었습니다.). 그런 다음 스트립을 튜브 주위에 단단히 감습니다, 튜브 외부 표면에 풋 베어링으로.

일반적인 핀 간격은 다음과 같습니다. 10 튜브 길이의 인치당 핀 — 이것은 다양할 수 있습니다.. 튜브를 감싸고 있는 핀 스트립의 장력은 핀 발을 튜브에 강력하게 안착시키는 역할을 합니다, 그리고 핀을 제자리에 단단히 고정합니다.

Datang에는 또한 관통되는 L 유형 탄미익 관 제조의 추가한 기능이 있습니다 (휠 핀이라고도 합니다.), 이는 일반 L-foot 핀과 구성이 동일합니다., 구멍이 규칙적인 간격의 방사형 간격으로 지느러미를 통해 천공된다는 점을 제외하고는.

공기 냉각기의 천공된 L-foot 핀 튜브에 대해 상당한 열 전달 이점이 주장되었습니다., 핀 표면의 중단이 공기가 핀 위로 흐를 때 핀에 쌓이는 정체된 공기 필름의 두께를 감소시킨다는 전제 하에. 이렇게 필름 두께가 감소하면 필름 계수가 증가합니다, 따라서 전체 열 전달 속도가 증가합니다..

향상된 열 전달 효율은 열 전달 표면적 요구 사항과 냉각기 크기를 줄일 수 있습니다, 또는 공기 흐름 및 팬 마력 요구 사항 감소.

알루미늄 L 형 핀 튜브는 일반적으로 초과하지 않는 저온 응용 분야에 사용됩니다. 350 화씨. 그들은 주로 대형 라디에이터와 같은 공랭식 응용 분야에 사용됩니다, 압축기 오일 쿨러, 및 기타 강제 드래프트 또는 유도 드래프트 공랭식 응용 분야.

이 제품에 대한 자세한 내용은 알루미늄 L-Foot 지느러미 튜브에 대한 Datang의 표준 사양을 참조하십시오..

'엘' / 'LL' /'KL' 타입 핀 튜브

‘L' 핀 튜브, 'LL' 핀 튜브, 'KLM' 핀 튜브 (핀 튜브 주위 랩):-

이 ‘L' 핀 튜브, 'LL' 핀 튜브, 'KLM' 핀 튜브는 랩 어라운드 핀 튜브라고도 합니다.. 이러한 유형의 핀 튜브는 열전달 온도가 상대적으로 낮고 비용을 제어해야 하는 곳에서 널리 사용됩니다. 이러한 유형의 핀 튜브는 'G' 유형 핀 튜브와 비교하여 비용이 상대적으로 저렴합니다. 압출 타입 핀 튜브.

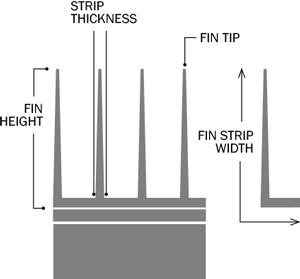

'L' 유형 핀 튜브 또는 'L' 풋 핀 튜브라고도 하는 핀에서 핀은 베이스 튜브 주위를 나선형으로 핀 스톡을 감싸서 수행됩니다. 이것은 나선형으로 감긴 핀 튜브라고도 하는 이유입니다. 지느러미 스톡의 바닥은 지느러미가 단단히 설 수 있는 기초를 제공하는 'L' 모양으로 되어 있습니다. 또한 'L'자 모양은 대기 부식에 대한 특정 보호 기능을 제공합니다.

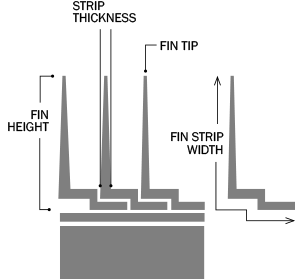

핀 튜브와 'L' 핀 튜브의 다음 버전은 'LL' 핀 튜브입니다. 이 과정은 L 핀 튜브 유형과 유사합니다.. 그렇지만, 개선 사항은 이전 핀의 'L' Foot이 다음 핀의 'L' Foot과 완전히 겹친다는 것입니다. 이것은 핀 베이스에 동시에 견인 'L'자 모양의 다리를 제공합니다.. 우수한 내식성을 제공합니다..

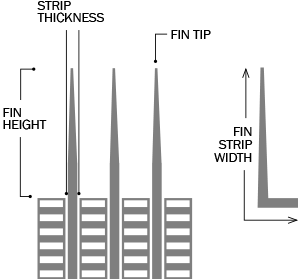

핀 튜브를 감싸는 마지막이자 가장 널리 사용되는 랩 유형은 'KLM' 핀 튜브 또는 '널링 L' 풋 핀 튜브입니다..

이것은 현재 가장 널리 사용되고 선호되는 핀 튜브 중 하나입니다.. 이 유형의 핀 튜브는 'L' 핀 튜브와 유사하게 제조됩니다. 그렇지만, 이 과정에는 튜브를 널링하는 동시에 핀 스톡의 'L' 베이스를 널링하여 프림 결합을 강화하고 핀과 튜브 사이의 훨씬 더 나은 접촉을 수행하는 작업이 포함됩니다.

위의 모든 유형의 핀 튜브 랩에서 핀은 나선형 장력에 의해 유지됩니다., 끝단은 기계적 결합을 통해 모이기 위해 단단히 고정되어야 합니다., 놋쇠로 만드는 etc.. 이 튜브는 또한 베이스 튜브의 두께가 훨씬 낮아 비용을 상당히 절감할 수 있는 추가적인 이점이 있습니다.

이 핀 튜브는 AIR FIN COOLERS에 적용됩니다., 라디에이터 등. 발전소와 같은 산업에서 선호됩니다., 화학 산업, 석유 정제소, 화학 공정 공장, 그리고 고무 식물 등.

'L' 핀 튜브의 특성, 'LL' 핀 튜브, 'KLM' 핀 튜브 (핀 튜브 주위 랩):-

-

제조공정: – Fin Base의 다양한 반복으로 Base Tube를 감쌉니다.

-

핀 투 튜브 본드 :- 온화한

-

열전달 효율 :- 온화한

-

기계적 저항: –온화한

-

부식 방지: –좋다

-

온도 범위:- 최대 175 데그 C

제조 범위 'L' 핀 튜브, 'LL' 핀 튜브, 'KLM' 핀 튜브 (핀 튜브 주위 랩):-

-

시니어. 아니요

내역

레인지

1

베이스 튜브 재질

스테인리스, 탄소강, 합금강, 타이타늄, 구리, 듀플렉스 스테인리스강, 인코넬 등. (이론적 한계 내의 모든 재료)

2

베이스 튜브 외경

12.70 mm에서 38.10 밀리미터

3

베이스 튜브 두께

1.25mm와 위에

4

베이스 튜브 길이

500 mm 최소 출력 15000 밀리미터

5

핀 재질

알루미늄, 구리, 스테인리스, 등.

6

핀 두께

0.3밀리미터, 0.35밀리미터, 0.4밀리미터, 0.45밀리미터, 0.55밀리미터, 0.60밀리미터, 0.65밀리미터

7

핀 밀도

236 FPM (에피엠) (6 증권 시세 표시기) 받는 사람 433 FPM (에피엠) (11 증권 시세 표시기)

8

핀 높이

9.8 mm에서 16.00 밀리미터

9

베어 엔드

클라이언트 요구 사항에 따라

10

제조 능력

5,00,000 연간 미터

우리는 원료 공급자와의 큰 주식 그리고 관계 때문에 긴급한 납품 기초에 물자를 공급해서 좋습니다. 우리는 프라임 품질 베이스 튜브와 알루미늄 소재만 사용합니다..

돌출된 것 핀 튜브s EN과 함께 제공될 수 있습니다. 10204 KO 3.1 및 EN 3.2 인증. 우리는 평판이 좋은 검사 기관에서 제 3 자 검사를 제공 할 수 있습니다..

L 핀 튜브

엘 핀 튜브

dtfinnedtube.com

dtfinnedtube.com