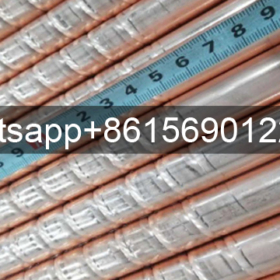

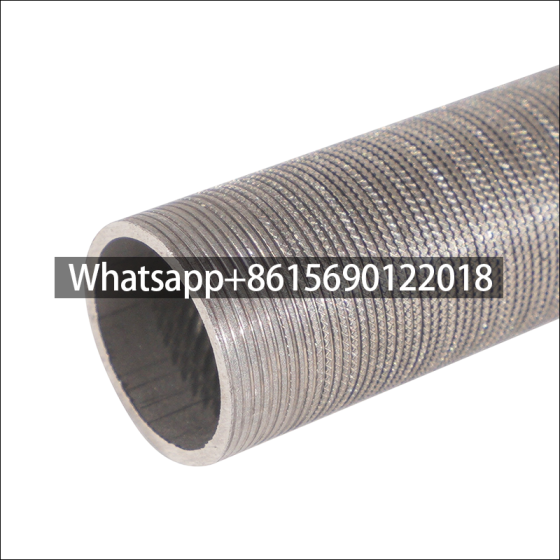

What is Corrugated Fin Tube?

Corrugated Fin Tube is a special-shaped smoke pipe that forms inner convex and outer concave spiral grooves on the surface of ordinary tubes through cold pressing. It is mainly used in the tail heating surface components of industrial boilers. Its geometric parameters include wall thickness, diameter, pitch and groove depth. The stiffness analysis is performed by the finite element method, and the model error does not exceed 5%.

Corrugated Fin Tube Core Features

Compared with ordinary light pipes, Corrugated Fin Tube can improve the boiler thermal efficiency by about 15%, reduce fuel consumption by 8%, and reduce the diameter of the boiler barrel by 30%-40%. Its enhanced heat transfer effect is significant, and the heat transfer volume of a threaded smoke pipe is equivalent to 1.7-1.8 times the same size light pipe.

Corrugated Fin Tube Application Scenario

Corrugated Fin Tube is mainly used for the transformation of coal-fired boilers, suitable for the capacity range of 0.7 to 140MW, and is commonly found in DZL type water and fire tube boilers and DZ type quick-load boilers.

Potential risks

Corrugated Fin Tube may experience dust accumulation, wear and composite corrosion problems during operation, and protective measures (such as regular cleaning, chemical deoxygenation, etc.) are required to extend the service life.

Corrugated Fin Tube

• All Kind of tube material can be applied as below

• Fin spec can be changed follow with client requirement.

• This is for use in Steam Condensing Heat Exchangers such as Power Plant Turbine

• Condenser, Feed Water Heater, and similar Application.

dtfinnedtube.com

dtfinnedtube.com