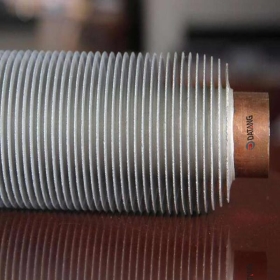

Use of extruded finned tube aluminum fins in boiler manufacturing

In modern industry, boilers are key heat energy conversion equipment, and their performance and efficiency are crucial to the entire production process. In order to improve heat exchange efficiency, reduce energy consumption and extend equipment life, manufacturers are constantly exploring the application of new materials and technologies.

As an efficient heat exchange element, extruded finned tube aluminum fins have been widely used in the field of boiler manufacturing. This article will discuss in detail why steel-aluminum finned tubes are chosen for boiler manufacturing, and analyze their advantages and application cases.

1. Basic characteristics of extruded finned tube aluminum fins

Extruded finned tube aluminum fins are a heat exchange tube made of composite materials, which consists of an inner steel tube and an outer aluminum fin. This structure combines the advantages of two materials: the steel tube has good mechanical strength and high temperature resistance, while the aluminum fin provides high thermal conductivity and a large surface area, which significantly improves the heat exchange efficiency. Specifically, steel-aluminum finned tubes have the following characteristics:

High strength and corrosion resistance: Steel tubes can withstand high working pressures and temperatures, and have good corrosion resistance to media such as water vapor and flue gas.

Efficient heat conduction: The thermal conductivity of aluminum is much higher than that of steel, which means that heat can be quickly transferred from the inside of the steel tube to the aluminum fins and then dissipated into the surrounding environment.

Lightweight structure: Compared with all-steel finned tubes, the steel-aluminum combination reduces weight and reduces transportation and installation costs.

Economical: Although aluminum is relatively expensive, its excellent thermal conductivity can reduce the number of fins required, thereby reducing overall costs.

2. Extruded finned tube aluminum fins improve heat exchange efficiency

During boiler operation, the high-temperature flue gas generated by fuel combustion needs to transfer heat to the working fluid (such as water or steam) through the heat exchange surface.

Traditional bare tube heat exchangers often have difficulty meeting the requirements of efficient heat exchange due to their limited surface contact area. In contrast, extruded finned tubes increase additional heat dissipation surface area, which greatly increases the heat transfer rate per unit volume.

After using aluminum extruded finned tubes, the thermal efficiency of the boiler can be increased by 5% to 10%, which means huge energy savings for large industrial boilers.

Extruded finned tube aluminum fins can also optimize fluid flow characteristics, reduce local resistance losses, and further improve the overall heat exchange effect.

For example, when designing, the airflow direction can be controlled by adjusting the fin spacing, angle, etc. to ensure uniform heat distribution, avoid “hot spots”, and protect the boiler from local overheating damage.

3. Extruded finned tube aluminum fins extend equipment life

In addition to improving efficiency, extruded finned tubes can also enhance the durability of boilers.

First, the steel tube part effectively isolates the internal high temperature environment from the relatively mild working conditions outside, preventing the aluminum fins from being directly exposed to extreme temperatures and reducing the risk of oxidation and corrosion.

Secondly, the aluminum fins themselves are also specially treated, such as anodizing or coating protection, to increase their durability and anti-pollution ability. Finally, reasonable structural design helps to disperse stress concentration points and reduce deformation or cracking problems caused by uneven thermal expansion.

Practical applications show that boilers using steel aluminum finned tubes have an average service life extended by about 20% compared to traditional models. This not only reduces the frequency of maintenance and replacement, reduces operating costs, but also improves the reliability and safety of the system.

4. Environmental benefits of aluminum extruded finned tubes

As the world pays more and more attention to environmental protection, energy conservation and emission reduction have become the common goal pursued by all walks of life.

The application of steel-aluminum finned tubes is a concrete manifestation of this trend. By improving the heat exchange efficiency, the consumption of fossil fuels is reduced, and the emission of pollutants such as carbon dioxide and nitrogen oxides is correspondingly reduced. According to statistics, each industrial boiler using steel-aluminum finned tubes can reduce thousands of tons of carbon emissions each year, making a positive contribution to the realization of green production and sustainable development.

In addition, steel-aluminum finned tubes can also be used in conjunction with waste heat recovery systems to reuse the low-grade heat energy that was originally wasted, provide auxiliary heating sources for other process links, form a complete energy cycle system, and maximize resource potential.

5. Application examples of aluminum fins of extruded finned tubes

At present, steel-aluminum finned tubes have been widely used in various types of boilers, including but not limited to:

Power station boilers: large coal-fired or gas-fired boilers used in power plants, which undertake the main heat exchange tasks.

Industrial boilers: serve the chemical, papermaking, textile and other industries, and provide necessary steam power support.

Hot water boiler: suitable for heating and hot water supply in public places such as schools, hospitals, and hotels.

Special boilers: such as waste incinerators, biomass boilers, etc., are customized for specific application scenarios.

Take a large chemical company as an example. The company introduced a waste heat boiler with steel-aluminum finned tubes in its newly built synthetic ammonia unit. After the implementation of the project, it not only successfully achieved the expected energy-saving goals, but also effectively supplied the by-product steam to the surrounding communities, creating significant social and economic benefits.

6. Extruded fin tube aluminum fin conclusion

Extruded fin tube aluminum fins have shown unparalleled advantages in the field of boiler manufacturing with their unique material combination, excellent heat exchange performance and wide range of applications.

In the future, with the continuous innovation and development of technology, it is believed that steel-aluminum finned tubes will be promoted and applied in more occasions, helping the industrial transformation and upgrading and ecological civilization construction in my country and even the world.

dtfinnedtube.com

dtfinnedtube.com