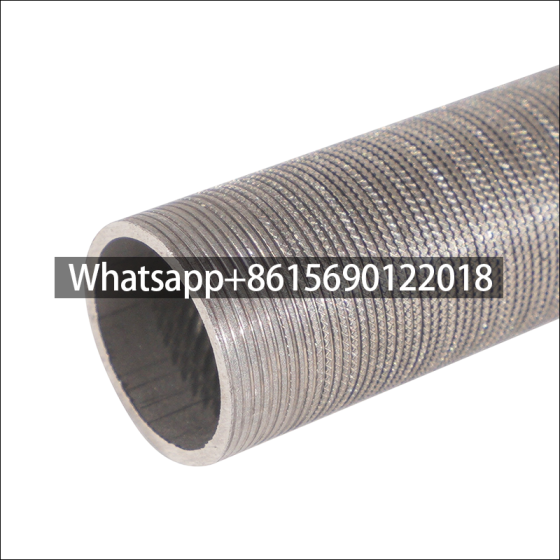

What are Integral Low Fin Tubes?

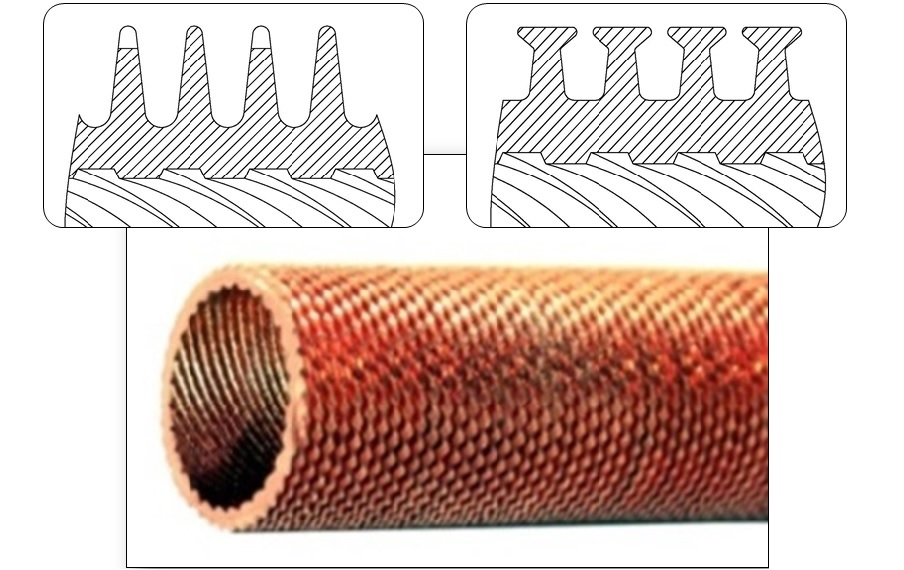

The ‘Integral Low Fin Tubes’ is also known as Integral Fin Tube,Low Fin Tube and Internally Finned Tubes.It is a finned tube obtained through plastic cold deformation.The method consists in realizing, from a smooth tube, fins with a particular geometric form without removing material; this plastic deformation causes an increment of heat exchange efficiency, and allows to reduce the heat exchanger size.

Integral Low Fin Tubes Process

The fins are manufactured rolling the Fin in the Base tube Itself. The fin height is relatively very low. However number of Fins Per inch or the fin Density can be increased greatly and improve the heat transfer area. The rolling is done on a special machine and the same can be supplied in straight as well as U bend configuration.

Integral low fin tubes are specifically designed tubes with enhanced surface area, accomplished through the process of integral finning. These tubes feature small fins that are seamlessly and mechanically attached to the outer surface,significantly increasing the heat transfer capability of the tube. The fins are precisely positioned, ensuring optimal turbulence and improved heat exchange performance.

Integral Low Finned Tubes specifications:

| Parameter | สเปค |

|---|---|

| Tube Material | เหล็กกล้าไร้สนิม, Copper, Carbon Steel, Titanium |

| Tube Outer Diameter (OD) | 12.7~25.4 mm |

| Tube Wall Thickness | 1.0~5.0 mm |

| Fin Material | – |

| Fin Outer Diameter (OD) | — |

| Fin Thickness | 0.3 mm |

| Fin Pitch | 26 FPI / 28 FPI / 30 FPI / 36 FPI / 43 FPI (Fins Per Inch) |

| Fin Height |

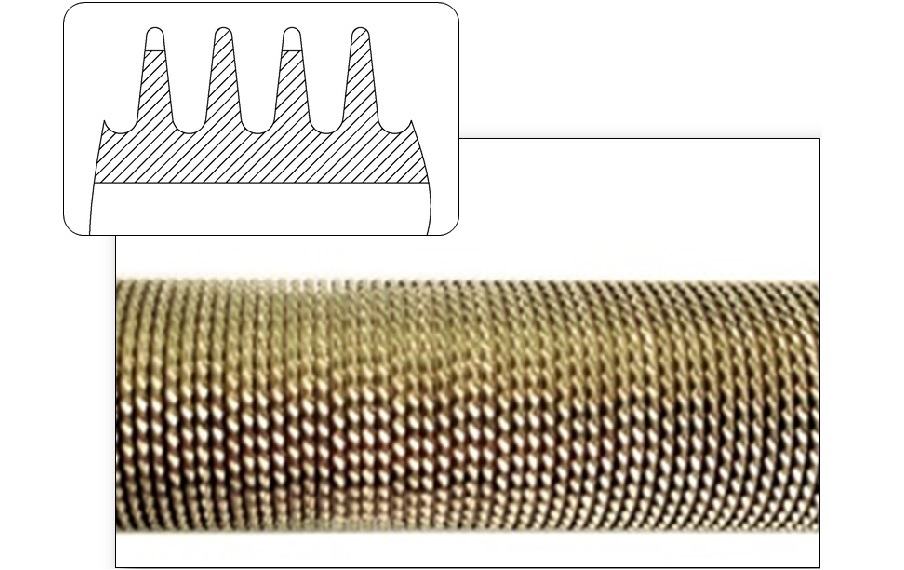

Condenser Tube (Y-fin)

Condenser tubes (Y-fin low finned tubes) are specific heat exchanger tubes that play important roles in the refrigeration cycle.

Condenser tubes are responsible for releasing heat from the refrigerant. They are typically located on the hot side of the system, where they transfer heat from the refrigerant to the surrounding fluid.

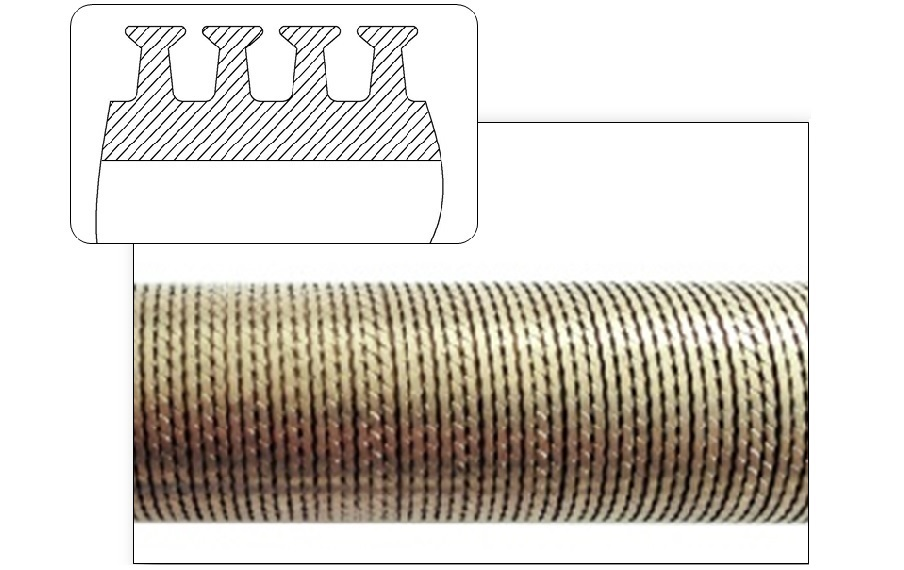

Evaporator Tube (T-fin)

Evaporator tubes (T-fin low finned tubes) are specific heat exchanger tubes that play important roles in the refrigeration cycle.

Evaporator tubes are usually located on the cold side of the system and are responsible for absorbing heat from the surrounding environment.

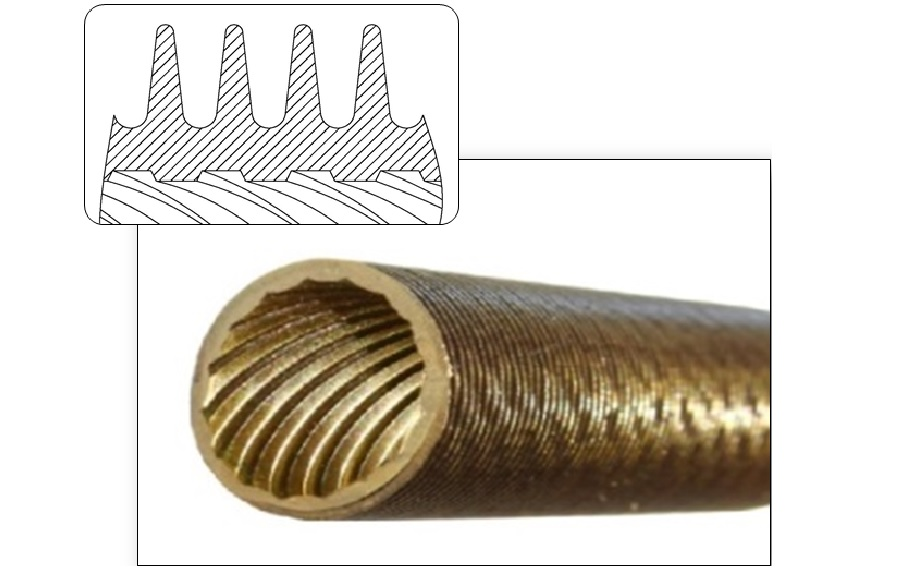

Inner Grooved (IG) ท่อครีบต่ํา

In several applications, heat exchangers could have a poor performance on tube side, so it is possible to increase inner heat transfer coefficient with low finned tubes with inner grooves.

Inner grooved tubes are heat exchanger tubes with helically formed grooves on the inner surface of the tube. These grooves create turbulence in the fluid flowing through the tube and increase the surface area in contact with the fluid, which improves heat transfer efficiency.

Knurled Finned Tubes or Diamond Finned Tubes

Knurled finned tubes (or Diamond finned tubes) are heat exchanger tubes with an unique diamond-shaped fin design.

This type of tubes are the best choice for inner tubes in leakage detector system.

Corrugated Finned Tubes

Corrugated finned tubes are specialized heat exchanger components designed to enhance heat transfer in various industrial applications with special focus on cleaning of tubes during their life. These tubes feature a corrugated or wavy finned surface on the outside, which increases their heat transfer efficiency compared to smooth-walled tubes.

The corrugated or wavy fins on the exterior of these tubes disrupt the boundary layer of air or fluid flowing over them. This disruption increases turbulence and promotes better heat transfer between the tube wall and the surrounding medium, whether it’s a gas or a liquid.

The corrugated design also helps reduce fouling on the tube surface by discouraging the accumulation of debris or deposits.

Integral Low Fin Tubes Advantages

1.Enhanced Heat Transfer Efficiency: The primary advantage of fin tubes lies in their remarkable heat transfer efficiency. The fins effectively augment the surface area, promoting better heat exchange between the fluid inside the tube and the surrounding environment. This translates to improved thermal performance and optimized energy consumption in heat transfer applications.

2. Compact Design: With their compact and efficient design, integral low fin tubes offer significant space-saving benefits. Their increased surface area allows for greater heat dissipation within a limited footprint, making them ideal for installations where space is a constraint.

3.Reduced Fouling: The finned structure of stainless steel finned tube heat exchangers mitigates the accumulation of deposits and fouling on the surface. This feature minimizes maintenance requirements and extends the operational lifespan of the tubes, resulting in cost savings and enhanced system reliability.

4.Versatile Applications: Finned copper tubing finds extensive applications across diverse industries. They are widely emploved in heat exchanqers, condensers, boilers, economizers. air coolers, and other thermal processes that demand efficient heat transfer. Whether it’s industrial HVAC systems, power generation plants, chemical processing units, or refrigeration applications, integral low fin tubes deliver exceptional performance.

5.Material Flexibility: Our integral low fin tubes are available in a variety of materials, including stainless steel and copper.

This allows you to choose the most suitable option based on your specific requirements, such as corrosion resistance, thermal conductivity, and operatinq conditions.

Applications – Integral Low Fin Tubes

–Heat exchangers for power plants (electric, nuclear, thermal and geothermal power plants)

–High corrosive systems (condensers, evaporators, sea water desalinations, fertilizing, urea systems, ammonia, gas, corrosive acids)

–Chemical and petrochemical industries

–Food processing and refrigeration industries.

Our Services

We can supply material on urgent delivery basis because of large stock and relations with raw material suppliers. We use only Prime Quality base tube and Aluminum Material.

Choosing Datang for your integral low fin tubes guarantees:

Customized Solutions: Our Finned Tubes are tailored to your specific system requirements, ensuring that your heat exchange systems operate at peak efficiency.

Durability and Reliability: The lightweight, corrosion-resistant aluminum construction ensures the longevity and reliability of our Finned Tubes.

Expertise and Innovation: With years of expertise in the industry, we are a trusted partner in enhancing the performance of your heat exchange systems.

We work hard to provide the highest quality products and services for our clients.

dtfinnedtube.com

dtfinnedtube.com