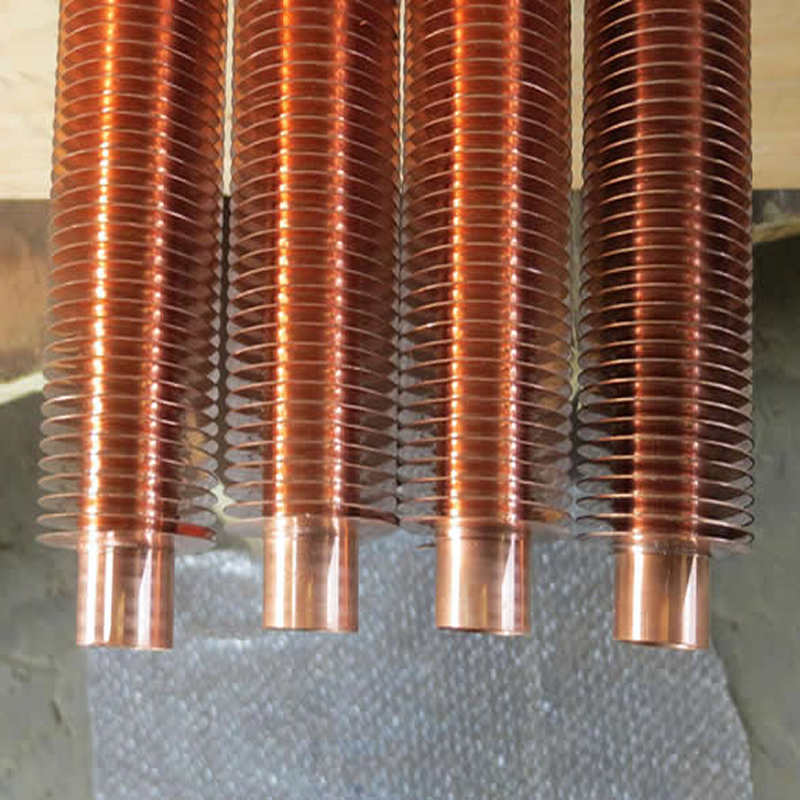

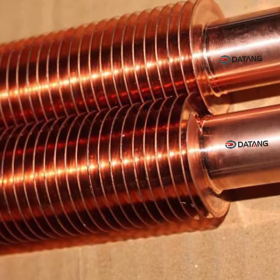

Integral copper high-finned tubes are heat exchange components that tightly bond fins to a copper base tube through high-frequency welding or integral rolling. They offer high heat transfer efficiency, résistance à la corrosion, and stability.

Structural Features of Integral Copper High Finned Tube

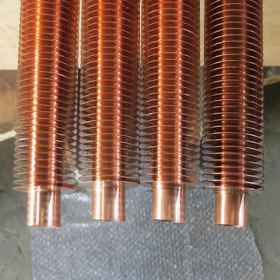

They integrate a copper alloy base tube (such as copper or brass) with high-thermal conductivity fins. High-frequency welding or three-roll cross-rolling creates a seamless connection, enhancing heat transfer efficiency and reducing fluid resistance. Fins are typically spiral or arranged longitudinally, and can be adapted for staggered or parallel configurations.

1. Structural Integrity: There is no contact thermal resistance between the fins and the base tube, eliminating the problem of looseness and reduced heat transfer efficiency associated with traditional wound fins.

2. Material Consistency: Typically, the same metal (such as copper, aluminium, stainless steel) or compatible alloys are used to ensure matching thermal expansion coefficients.

3. Process Variety: Various forming methods, including rolling, extrusion, and welding, can be selected based on specific needs.

Comparison of Integral Copper High Finned Tube Manufacturing Processes

1. Rolling:

– Helical fins are formed by plastically deforming the surface metal of the base tube through rolling. Suitable for materials such as carbon steel and stainless steel.

– Advantages: Low cost, high production efficiency, and adjustable fin density (typically 4-12 fins/inch).

2. Welding:

– Prefabricated fins are laser welded to the base tube. Suitable for high-temperature and high-pressure environments (such as power plant boilers).

– Typical parameters: Weld tensile strength ≥ 300 MPa (ASME standard).

3. Extrusion:

– Fins are extruded from an aluminum tube through a die. Commonly used in air conditioning condensers, the fin thickness is only 0.3-0.8 mm. Integral Copper High Finned Tube Advantages

High-Efficiency Heat Transfer: Increased surface area improves heat transfer efficiency.

Corrosion Resistance: Copper alloys are stable in humid or corrosive environments.

Compact Structure: The integrated design reduces installation and maintenance costs.

Stability: High-frequency welding or integral rolling ensures long-term reliability.

Applications of Integral Copper High Finned Tube

Suitable for high-temperature and high-pressure environments such as air conditioning and refrigeration systems, industrial boilers, and chemical reactors, it offers both corrosion resistance and wear resistance. Par exemple, it can improve cooling efficiency in air conditioning condensers and enhance heat exchange in boiler heat exchangers.

Finned tubes have a wide range of applications. In thermal power plants, finned tubes are used as key components in air preheaters, waste heat boilers, and steam turbines, significantly improving thermal energy utilization.

Finned tubes also play an irreplaceable role in oil refining and natural gas extraction, providing efficient and stable solutions for heating, refroidissement, and hot water supply.

Finned tubes are also widely used in the chemical industry. Finned tubes serve as core heat exchange equipment in the production of fertilizers, sulfuric acid, acetic acid, methanol, and other chemical products. They improve reaction speed and product purity, providing a strong guarantee for the smooth operation of chemical production.

Finned tubes also demonstrate their unique value in the fields of environmental protection and household appliances. They play a vital role in waste heat treatment systems in nuclear power plants, chemical wastewater treatment equipment, and agricultural irrigation water purification.

In household appliances, the evaporators, condensers, and radiators of air conditioners, refrigerators, and water heaters are also designed and manufactured based on finned tubes, achieving efficient and stable cooling and heating functions.

dtfinnedtube.com

dtfinnedtube.com