Enhanced Surface Tubes with Integral Low-Fin Structures for Shell-and-Tube Heat Exchangers and Oil/Gas Coolers

1. Enhanced Surface Tubes Integral Low Fin Tube Introduction

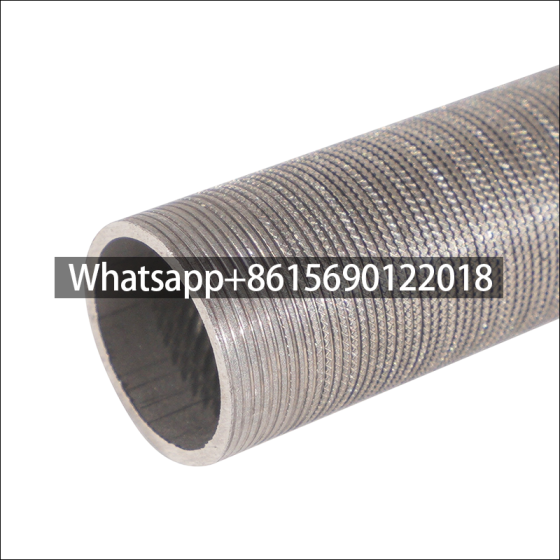

Enhanced surface tubes, particularly integral low-fin tubes, have become critical components in modern shell-and-tube heat exchangers and oil/gas cooling systems. These tubes are designed with extended fin surfaces to improve thermal performance while maintaining structural integrity. Their applications span industries such as petrochemical, power generation, and HVAC, where efficient heat transfer and compact designs are essential.

2. Enhanced Surface Tubes Integral Low Fin TubeDesign and Manufacturing

Integral low-fin tubes are manufactured through precision machining or cold-forming processes that create helical or longitudinal fins directly from the base tube material (typically copper, stainless steel, or titanium). Key features include:

- Fin Density: Typically 11–40 fins per inch (FPI) for optimal turbulence and surface area enhancement.

- Fin Height: Low-profile fins (0.5–2 mm) balance fouling resistance and heat transfer efficiency.

- Materials: Corrosion-resistant alloys for harsh environments (e.g., seawater coolers).

3. Enhanced Surface Tubes Integral Low Fin Tube Thermal Performance Advantages

- Increased Surface Area: Low fins augment heat transfer area by 2–3× compared to smooth tubes.

- Enhanced Turbulence: Fin structures disrupt laminar flow, reducing thermal boundary layer resistance.

- Fouling Mitigation: Spiral fins minimize particulate deposition in oil/gas applications.

4. Enhanced Surface Tubes Integral Low Fin Tube Applications

- Shell-and-Tube Heat Exchangers: Ideal for condensers and evaporators due to high ΔT efficiency.

- Oil/Gas Coolers: Widely used in upstream and midstream processes where compactness is critical.

5. Enhanced Surface Tubes Integral Low Fin Tube Challenges and Future Trends

- Cost: Precision machining increases production expenses.

- Material Innovation: Additive manufacturing may enable complex fin geometries.

- Hybrid Designs: Combining low fins with micro-scale surface treatments (e.g., nanostructured coatings).

6. Enhanced Surface Tubes Integral Low Fin Tube Conclusion

Integral low-fin tubes offer a robust solution for enhancing heat exchanger performance. Future advancements in materials and manufacturing will further expand their industrial applicability.

dtfinnedtube.com

dtfinnedtube.com