Low Fin Tube

- Fin Tube

- Finned Tube

- Finned Copper Tube

- Fins For Float Tube

- Heat Exchanger

- Heat Exchangers

- Furnace Heat Exchanger

- Pool Heat Exchanger

- Water Heat Exchanger

- Fin Tube Element

- Air Preheater

- Finned Tube Machine

- Economizer

- Fin Tube Radiator

- Evaporator

- Extruded Fin Tube

- G Type Embedded Fin Tube

- L KL LL Type Fin Tube

- H/HH Type Fin Tube

- Welded Longitudinal Finned Tube

- Air Cooler

- High Frequency Welded Fin Tube

- Serrated Fin Tube

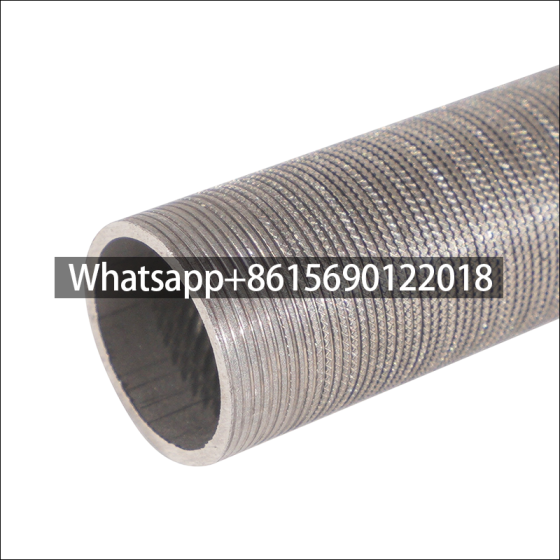

- Low Fin Tube

- Internally Finned Tube

- Elliptical fin tube

- Laser Welding Fin Tube

- Finned Tube Heat Exchanger

- Air-Temperature Vaporizer

- Electric Heat Tube

Low fin tubes are generally machined to form fins of a certain height, a certain fin pitch, and a certain thickness on the outer surface of the light tube.

Mainly used in air-conditioning and refrigeration equipment (condensers, evaporators), the heat exchange efficiency is improved by increasing the surface area. It is also used in high-temperature and high-pressure scenarios such as boilers and electricity in the industrial field, but the search results do not clearly mention specific application cases.

Common materials include carbon steel, stainless steel, copper, aluminum alloy, etc., among which stainless steel 304/316, duplex steel 2205 and other materials can adapt to more complex working conditions. Parameters such as fin height and fin pitch are controlled through process to optimize heat exchange performance and anti-deformation ability.

dtfinnedtube.com

dtfinnedtube.com

WeChat

Scan the QR Code with WeChat