Unveiling the Superiority of Our Carbon Steel Finned Tube

1. Introduction to a Vital Component

In the complex and demanding world of power station operations, the finned tube emerges as a linchpin of efficient heating systems. Our finned tube, meticulously engineered and designed, is set to revolutionize the way heat is managed and transferred within power station boilers.

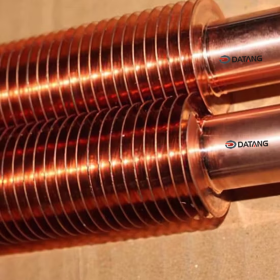

2. Material Composition and Quality

The tube is constructed from high-quality carbon steel, Advanced High Efficiency Spiral Finned Tube Ideal for Boiler Economizer Systems Optimization renowned for its robustness and ability to withstand high pressures and temperatures. This material choice not only ensures the structural integrity of the finned tube but also provides an excellent base for heat conduction. Paired with aluminum fins, which possess remarkable thermal conductivity properties, the combination creates a synergy that maximizes heat transfer efficiency. The aluminum fins, with their lightweight yet highly conductive nature, act as extensions of the heat transfer surface, allowing for rapid dissipation and absorption of heat.

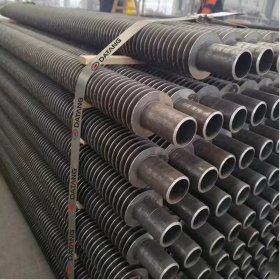

3. Surface Treatment and Durability

Featuring a natural surface treatment, our commercial finned tube retains its inherent material characteristics while also presenting a clean and unaltered exterior. This natural finish is not only aesthetically pleasing but also offers a certain level of resistance to environmental factors. In the context of a power station where various substances and conditions may be present, the tube’s durability is further enhanced. The compatibility with oil fuel is another crucial aspect. In power stations where oil is often used as a fuel source, the finned tube is designed to handle the specific chemical and thermal properties associated with oil combustion. It can endure the corrosive by-products and high-temperature fluxes that occur during the fuel burning process, ensuring a long service life and consistent performance.

4. Customization and Specifications

We understand that every power station has unique requirements and operational parameters. That’s why our finned tube offers customized specifications. Whether it’s a particular length, diameter, or fin spacing, we can tailor the product to meet the exact needs of your power station’s boiler system. This level of flexibility allows for seamless integration into existing setups or the creation of bespoke heating solutions for new installations. The ability to customize also extends to the overall design and performance characteristics, ensuring that the finned tube optimally matches the specific heat transfer demands of the power station.

5. Brand Reputation and Origin

Carrying the respected datang trademark, our finned tube is associated with a legacy of quality and reliability. The datang brand has been synonymous with excellence in the industry, known for delivering products that meet and exceed international standards. Originating from China, a global manufacturing powerhouse with a wealth of experience and technological expertise in metal fabrication, our finned tube benefits from the country’s advanced manufacturing infrastructure and skilled workforce. The combination of a renowned brand and a country with a proven track record in manufacturing instills confidence in our customers, assuring them that they are investing in a top-tier product.

6. Production Capacity and Order Flexibility

With an astounding production capacity of 800000 ton/Year, we are well-equipped to handle both large-scale power station projects and smaller orders. The minimum order quantity (MOQ) of just 1PCS is a testament to our commitment to serving a diverse range of customers. Whether you are a major power utility looking to outfit an entire fleet of boilers or a small-scale power generation facility in need of a single replacement part, we can accommodate your needs. Additionally, our flexible transport options, including packaging in bundles or wooden cases, ensure that the finned tubes are delivered safely and securely to their destination, ready for immediate installation and use.

7. Application and Performance in Power Stations

Specifically designed for use as heater parts in power station boilers head, our finned tube plays a pivotal role in the overall heating process. Finned Tubes Versatile Components for Efficient Heat Transfer It efficiently transfers heat from the combustion source to the working fluid, whether it be water or steam, ensuring that the power station operates at optimal efficiency. By enhancing the heat transfer rate, it helps to reduce fuel consumption, lower emissions, and increase the overall productivity of the power station. The reliable performance of our finned tube under the harsh and continuous operating conditions of a power station is a key factor in maintaining the uninterrupted supply of electricity to the grid.

In conclusion, our carbon steel finned tube is a technological marvel that combines superior materials, customization options, brand reputation, and high production capacity. It is the ideal solution for power stations seeking to enhance their heating systems’ performance, reliability, and longevity. With its ability to adapt to diverse requirements and withstand the rigors of power generation, it stands as a cornerstone of modern power station technology.

dtfinnedtube.com

dtfinnedtube.com

WeChat

Scan the QR Code with WeChat