The Pinnacle of Heat Transfer Technology: Our Finned Tube

1. Introduction: Revolutionizing Heat Transfer

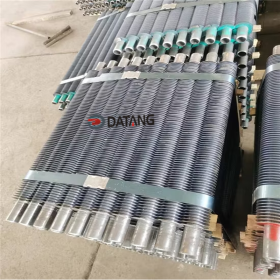

In the ever-evolving realm of industrial processes and technological advancements, Premium Stainless Steel Spiral Fins Tube for Enhanced Heat Transfer Efficiency efficient heat transfer is the cornerstone of success. Our finned tube represents a quantum leap in heat exchange solutions, engineered to meet the most demanding requirements of modern applications.

2. Certification and Global Standards Compliance

Our commitment to quality is unwavering, as evidenced by the prestigious CE and ISO certifications adorning our finned tube. These certifications are not mere labels but a guarantee of adherence to the most stringent international norms. The CE mark ensures conformity with European health, safety, and environmental protection standards, making our product suitable for a wide range of European and global markets. The ISO certification, on the other hand, attests to our implementation of a comprehensive quality management system, covering every aspect from design and manufacturing to installation and servicing. This dual accreditation instills confidence in our customers, assuring them that they are investing in a product that has undergone rigorous scrutiny and meets the highest benchmarks of quality and reliability.

3. Unrivaled Versatility in Applications

The applications of our finned tube span across multiple industries and critical processes. In the domain of heating, it serves as a catalyst for efficient energy conversion, whether in industrial furnaces, space heaters, or water heating systems. By maximizing heat transfer, it ensures rapid and uniform heating, thereby enhancing overall system performance and reducing energy consumption.

As a cooler, it plays a pivotal role in maintaining optimal operating temperatures in a host of applications. In power plants, it helps cool down turbines and generators, preventing overheating and ensuring continuous and reliable power generation. In the automotive industry, it is an essential component in engine cooling systems, safeguarding against engine damage due to excessive heat.

In vaporization processes, such as in distillation columns and evaporators, our finned tube accelerates the conversion of liquids into vapors. Its enhanced surface area and efficient heat transfer characteristics enable rapid vaporization, improving process efficiency and throughput.

When it comes to condensation, it excels in recovering valuable vapors and converting them back into liquids. In refrigeration and air conditioning systems, it is the key element in the condenser unit, facilitating the release of heat and enabling the refrigerant to cycle back and repeat the cooling process.

In heat exchangers, which are the workhorses of many industrial processes, our finned tube forms the core. It enables the seamless transfer of heat between two fluids, be it in chemical plants for process heat recovery, in oil refineries for heat exchange between different process streams, or in HVAC systems for heating and cooling indoor spaces.

In air coolers and radiators, it dissipates heat from fluids or gases into the surrounding air. In industrial machinery, it helps maintain the temperature of hydraulic fluids and lubricants, ensuring smooth operation and prolonging equipment life. In electronics cooling, it prevents overheating of sensitive components, enhancing the reliability and lifespan of electronic devices.

And in economizers, it emerges as a champion of energy conservation. By recovering waste heat from exhaust gases or other sources and transferring it to incoming fluids, it significantly reduces fuel consumption and greenhouse gas emissions. This makes it an indispensable component in power plants, boilers, and industrial furnaces, contributing to sustainable and cost-effective operations.

4. The Science Behind the Mixing Heat Exchanger Principle

The Mixing Heat Exchanger principle upon which our finned tube operates is a marvel of thermodynamic engineering. Unlike traditional heat exchangers that rely solely on conduction and convection across a solid wall, our finned tube promotes the active mixing of hot and cold fluids. This mixing is achieved through the strategic design of the tube and its fins. The fins, which can be customized in thickness and configuration, create turbulence in the fluid flow. As the hot and cold fluids interact within this turbulent environment, heat is transferred at a much faster rate. The increased surface area provided by the fins further amplifies the heat transfer process. The unique shape and arrangement of the fins disrupt the laminar boundary layer of the fluids, enhancing the convective heat transfer coefficient. This results in a more efficient and rapid exchange of thermal energy, enabling our finned tube to achieve higher heat transfer rates compared to conventional designs.

5. Material Selection: Tailoring to Every Need

Our finned tube is available in a diverse range of materials, each carefully chosen to meet specific application requirements. Carbon Steel, with its excellent strength and cost-effectiveness, is a popular choice for applications where high pressure and moderate corrosion resistance are sufficient. It is widely used in industrial steam boilers and some chemical processing applications where the operating environment is not overly corrosive.

Stainless Steel, on the other hand, offers outstanding corrosion resistance, making it the material of choice for applications in harsh chemical environments, food and beverage processing, and pharmaceutical industries. Its ability to withstand the corrosive effects of acids, alkalis, and other aggressive substances ensures the longevity and reliability of the finned tube in these critical applications.

Aluminum, renowned for its lightweight nature and good thermal conductivity, is ideal for applications where weight is a crucial factor. It is commonly used in aerospace and automotive industries for heat exchangers and cooling systems, where reducing weight without compromising heat transfer efficiency is of utmost importance.

Copper, with its exceptional thermal conductivity, The All Powerful Tube Type Heat Exchanger: Unraveling Its Secrets is the go-to material for applications that demand rapid heat transfer. It is widely used in high-performance heat exchangers, such as those in computer cooling systems and some specialized industrial processes where high heat fluxes need to be managed.

Alloy Steel combines the best of multiple metals, offering enhanced strength, corrosion resistance, and temperature resistance. It is often used in applications that require a combination of these properties, such as in high-pressure and high-temperature industrial reactors and some offshore oil and gas applications.

The ability to customize the fin thickness is another unique feature of our finned tube. By adjusting the fin thickness, we can optimize the heat transfer performance based on the specific thermal requirements of the application. Thicker fins may be used in applications where a higher heat transfer rate is needed, while thinner fins may be more suitable for applications where pressure drop and weight are concerns.

6. Performance Excellence: Pressure, Temperature, and Corrosion Resistance

Our finned tube is engineered to perform under the most challenging conditions. In terms of pressure resistance, it is designed to withstand high internal and external pressures. The robust construction and carefully selected materials ensure that the tube maintains its integrity even in high-pressure steam systems, hydraulic circuits, and other applications where pressure differentials are significant.

When it comes to temperature resistance, our finned tube can operate effectively across a wide temperature spectrum. From cryogenic temperatures in liquefied gas storage and transportation systems to extremely high temperatures in industrial furnaces and power plant boilers, it retains its mechanical and thermal properties. This wide temperature range of operation makes it a versatile solution for a multitude of industries and applications.

Corrosion resistance is another area where our finned tube excels. The choice of materials such as Stainless Steel and Alloy Steel, along with proper surface treatments and coatings, provides protection against corrosion. This is crucial in applications where the finned tube is exposed to corrosive fluids, gases, or humid environments. By withstanding corrosion, the tube maintains its heat transfer efficiency and structural integrity over its service life, reducing maintenance costs and downtime.

7. Customization and Flexibility: Meeting Unique Requirements

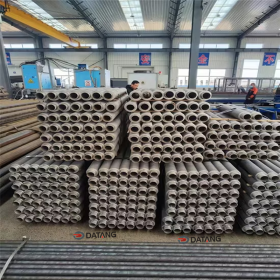

We understand that every project has its own set of unique requirements and constraints. That’s why our finned tube offers extensive customization options. The base tube length, which can range from 0 to 22 meters, allows for seamless integration into various system designs. Whether it’s a compact heat exchanger for a small-scale industrial process or a long tube bundle for a large power plant economizer, we can manufacture the finned tube to the exact length needed.

In addition to length customization, we also offer flexibility in fin design, including fin pitch, fin height, and fin shape. These parameters can be adjusted to optimize heat transfer performance based on the specific fluid properties, flow rates, and operating conditions of the application. This level of customization ensures that our finned tube is not a one-size-fits-all solution but rather a tailored component that maximizes the efficiency of each individual heat transfer system.

8. Packaging, Origin, and Production Capacity: A Complete Package

To safeguard our china finned tube during transportation and storage, it is packaged in a high-quality plywood transport package. This packaging is designed to protect the tube from physical damage, moisture, and other environmental factors. It ensures that the finned tube arrives at the customer’s site in pristine condition, ready for installation and immediate use.

Originating from China, a global manufacturing powerhouse, our finned tube benefits from the country’s advanced manufacturing technologies, a large pool of skilled labor, and a well-established supply chain. This enables us to produce high-quality finned tubes at a competitive cost and with a remarkable production capacity of 800000PCS/Year. Our efficient production processes and quality control systems ensure that each finned tube meets the exacting standards set by our customers and international certifications.

In conclusion, our finned tube is a technological masterpiece that combines innovation, quality, versatility, and performance. Whether you are in the power generation, chemical processing, HVAC, or any other industry that relies on efficient heat transfer, our finned tube is the ultimate solution. With its wide range of applications, advanced operating principle, diverse material options, outstanding performance characteristics, customization capabilities, reliable packaging, and significant production capacity, it is poised to transform the way you approach heat transfer and take your industrial processes to new heights of efficiency and reliability.

dtfinnedtube.com

dtfinnedtube.com

WeChat

Scan the QR Code with WeChat