Unveiling the Superiority of Our Stainless Steel Finned Tube

1. Introduction: A Revolution in Heat Exchange

In the highly competitive field of heat transfer technology, our stainless steel finned tube emerges as a paragon of innovation and excellence. Engineered with meticulous precision and a deep understanding of thermodynamic principles, it is designed to redefine the standards of efficiency and reliability in heat exchange applications.

2. The Core Principle: Mixing Heat Exchanger

At the heart of this remarkable finned tube lies the Mixing Heat Exchanger principle. Unlike traditional heat exchangers that rely mainly on conduction through solid walls, our design promotes the active mixing of hot and cold fluids. This is achieved through a carefully engineered internal structure that creates turbulence and facilitates direct contact between the two fluid streams. As a result, heat is transferred at a much faster rate, maximizing the overall heat exchange efficiency. This principle not only accelerates the transfer of thermal energy but also minimizes temperature gradients, ensuring a more uniform heat distribution. It is this unique approach that sets our finned tube apart from conventional alternatives, making it ideal for applications where rapid and efficient heat transfer is of utmost importance.

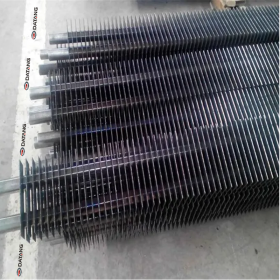

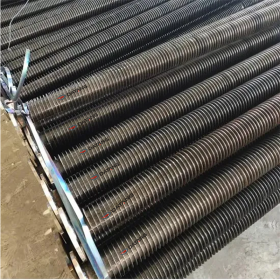

3. Material and Construction: The Power of Stainless Steel

The choice of stainless steel as the primary material for our finned tube is a testament to its durability and versatility. Stainless steel is renowned for its excellent corrosion resistance, which enables the tube to withstand harsh environmental conditions and corrosive fluids. This property is crucial in applications such as chemical processing plants, where exposure to acids, alkalis, and other corrosive substances is common. Additionally, stainless steel offers high strength and thermal conductivity, ensuring that the tube can handle high pressures and efficiently transfer heat. The steel type style of construction further enhances the tube’s mechanical integrity, allowing it to maintain its shape and performance even under extreme operating conditions. This combination of material and construction qualities makes our finned tube a reliable and long-lasting solution for a wide range of heat exchange needs.

4. Quality Assurance: Rigorous Inspection by SGS BV

To guarantee the highest level of quality and performance, Copper Screw Thread Heat Condenser Finned Tube or Radiator our finned tube undergoes a comprehensive inspection process by SGS BV, a globally recognized leader in independent testing and certification. SGS BV’s experts conduct a series of tests and evaluations, examining every aspect of the tube’s design, manufacturing, and material composition. This includes checks for dimensional accuracy, surface finish, and mechanical properties. By subjecting our product to such rigorous scrutiny, we ensure that it meets and exceeds international quality standards. The SGS BV certification not only provides our customers with peace of mind but also serves as a mark of distinction, setting our finned tube apart from competitors in the market.

5. Specifications and Customization: Tailored to Your Needs

The 1007060 specification of our finned tube is carefully designed to offer a balance between heat transfer surface area and fluid flow characteristics. However, we understand that different applications may require unique dimensions and configurations. That’s why we offer customization options to meet the specific requirements of our customers. Whether it’s a different tube diameter, fin height, or fin spacing, our team of engineers can work with you to develop a finned tube solution that optimally fits your application. This flexibility allows our product to be integrated seamlessly into a wide variety of heat exchange systems, from small-scale industrial heaters to large power plant condensers.

6. Packaging and Origin: Safe Delivery from China

To ensure that our finned tube arrives at its destination in pristine condition, finned copper tube it is packaged in high-quality plywood. This packaging material provides excellent protection against physical damage during transit, safeguarding the tube from impacts, vibrations, and environmental factors. Our finned tube proudly originates from China, a global manufacturing hub known for its advanced manufacturing technologies and skilled workforce. With a rich history of producing high-quality industrial products, China offers a reliable and cost-effective manufacturing base for our finned tube. The HS Code 7306400000 further classifies and regulates the international trade of our product, ensuring smooth customs clearance and compliance with global trade regulations.

7. Production Capacity and Market Leadership: Meeting Your Demands

With a remarkable production capacity of 800000PCS/Year, we are well-positioned to meet the demands of both small and large customers. Our state-of-the-art manufacturing facilities and efficient production processes enable us to scale up production quickly and maintain consistent quality. This high production volume not only allows us to serve a large customer base but also contributes to cost savings, which we can pass on to our customers. Our finned tube, bearing the datang trademark, has gained a reputation for excellence in the market. The datang brand is synonymous with quality, reliability, and innovation, making our product a top choice for engineers and procurement professionals seeking the best heat exchange solution.

In conclusion, our stainless steel finned tube offers a unique combination of advanced heat exchange principle, high-quality material, strict quality assurance, customization options, reliable packaging, and significant production capacity. Whether you are involved in industrial heating, cooling, or any other heat transfer application, our finned tube is the ideal choice to enhance your system’s performance and efficiency.

dtfinnedtube.com

dtfinnedtube.com

WeChat

Scan the QR Code with WeChat