L type Fin Tube for Heat Exchanger

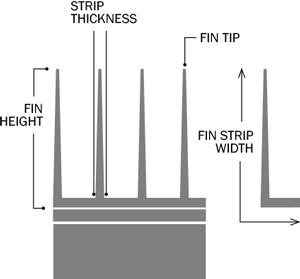

Datang’s Aluminum L type Fin Tubes consist of thin aluminum fin strip tightly wound helically around the tube circumference. An L-shaped foot, 1/16″ wide, is first formed on one side of the fin strip (hence the name L-Foot). The strip is then wound tightly around the tube, with the foot bearing on the tube outer surface.

A typical fin spacing is 10 fins per inch of tube length — this can be varied. Tension in the fin strip as it is wrapped around the tube serves to seat the fin foot forcefully on the tube, and to hold the fin firmly in place.

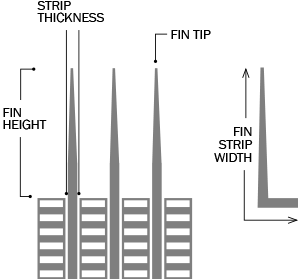

Datang also has the added capability of manufacturing Perforated L type Fin Tubes (sometimes referred to as wheel fin), which is identical in configuration to the regular L-foot fin, except that holes are perforated through the fins at regularly spaced radial intervals.

Significant heat transfer advantages have been claimed for perforated L-foot finned tubes in air coolers, under the premise that interruptions in the fin surface reduce the thickness of the stagnant air film that builds up on the fin as air flows over it. This reduced film thickness results in an increased film coefficient, thereby increasing overall heat transfer rate.

The improved heat transfer efficiency can reduce heat transfer surface area requirements and cooler size, or reduce airflow and fan horsepower requirements.

Aluminum L type Fin Tubes are typically used in low temperature applications not exceeding 350 degrees F. They are primarily used in air-cooled applications such as large radiators, compressor oil coolers, and other forced-draft or induced-draft air-cooled applications.

To learn more about this product see Datang’s Standard Specifications for Aluminum L-Foot Finned Tubes.

‘L’ / ‘LL’ /’KL’ TYPE FIN TUBE

‘L’ FIN TUBE, ‘LL’ FIN TUBE, ‘KLM’ FIN TUBE (WRAP AROUND FIN TUBE):-

The ‘L’ FIN TUBE, ‘LL’ FIN TUBE, ‘KLM’ FIN TUBE also known as Wrap Around Fin Tube. This type of Fin Tube widely finds acceptance where the Heat Transfer Temperature is relatively lower and the cost needs to be controlled. These type of Fin Tubes are relatively lesser in cost as compared to the ‘G’ Type Fin Tube and the Extruded Type Fin Tube.

In ‘L’ Type Fin Tube or also known as ‘L’ Foot Fin Tube the finning is done by wrapping around the Fin stock spirally around the base tube. This is as reason also known as spirally wound Fin Tube. The base of the fin stock is Shaped in to and ‘L’ shape which gives a base for the fin to stand on firmly. Also the ‘L’ shape provides a certain protection against the atmospheric corrosion.

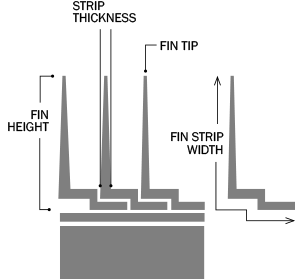

The next version of wrap around Fin Tube and also of ‘L’ Fin Tube is ‘LL’ Fin Tube. The process is similar to the L Fin Tube type. However, the improvement is that the ‘L’ Foot of the previous fin is completely overlapped by the ‘L’ Foot of the next fin. This gives the Fin base a shape of tow ‘L’ foot simultaneously. It provides excellent corrosion resistance.

The last and the most widely used type of wrap around Fin Tube is ‘KLM’ Fin Tube or ‘Knurled L’ Foot Fin Tube.

This is currently one of the most widely type used and preferred Fin Tubes. This type of Fin Tube is manufactured similar to the ‘L’ Fin Tube. However, the process involves Knurling the Tube and at the same time the ‘L’ base of the fin stock to firm a frim bond and much better contact between the Fin and the Tube.

In all the above type of wrap around Fin Tubes the fins are held by Spiral Tension, The ends are required to be firmly held to gather by means of Mechanical Bonding, Brazing etc. This tube also has an added benefit of using Much Lower Thickness of the Base tube thereby reducing the cost considerably.

These Fin Tubes find application in AIR FIN COOLERS, RADIATORS etc. and are preferred in Industries like Power Plants, Chemical Industries, Petroleum Refineries, Chemical process Plants, and Rubber Plants etc.

Properties of ‘L’ FIN TUBE, ‘LL’ FIN TUBE, ‘KLM’ FIN TUBE (WRAP AROUND FIN TUBE):-

-

Manufacturing Process: – Wrap Around the Base Tube with various iterations of the Fin Base

-

Fin To Tube Bond :- Moderate

-

Heat Transfer Efficiency :- Moderate

-

Mechanical Resistance: – Moderate

-

Corrosion Protection: – Good

-

Temperature Range:- Up to Maximum 175 Deg C

Manufacturing Range ‘L’ FIN TUBE, ‘LL’ FIN TUBE, ‘KLM’ FIN TUBE (WRAP AROUND FIN TUBE):-

-

Sr. No

Particulars

Range

1

Материал базовой трубки

Нержавеющая сталь, Carbon Steel, Alloy Steel, Titanium, Медь, Duplex Stainless Steel, Inconel etc. (all material in the theoretical limit)

2

Base Tube Outside Diameter

12.70 mm to 38.10 миллиметр

3

Base Tube Thickness

1.25mm And Above

4

Длина базовой трубы

500 mm Min To 15000 миллиметр

5

Материал оребрения

Aluminum, Медь, Нержавеющая сталь, etc.

6

Толщина ребер

0.3миллиметр, 0.35миллиметр, 0.4миллиметр, 0.45миллиметр, 0.55миллиметр, 0.60миллиметр, 0.65миллиметр

7

Fin Density

236 FPM (6 FPI) to 433 FPM (11 FPI)

8

Высота плавников

9.8 mm to 16.00 миллиметр

9

Bare Ends

As per Client Requirement

10

Manufacturing Capacity

5,00,000 Meter Per Annum

We can supply material on urgent delivery basis because of large stock and relations with raw material suppliers. We use only Prime Quality base tube and Aluminum Material.

The Extruded Ребристая трубкаs can be supplied with EN 10204 EN 3.1 and EN 3.2 certifications. We can provide Third Party Inspection from any reputed inspection agency.

L Ребристая трубка

LL Ребристая трубка

dtfinnedtube.com

dtfinnedtube.com