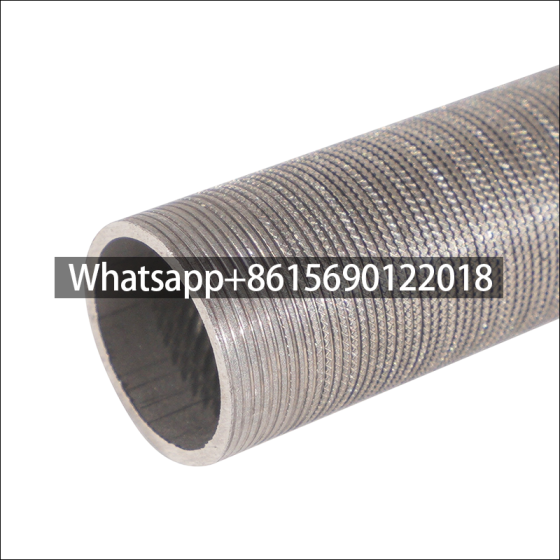

Internally Threaded Metal Finned Tube & Pipe for Evaporators and Condensers

The internal threaded metal finned tube is a high-efficiency heat exchange element that combines internal thread-embedded tubing to enhance heat transfer and external fins to increase surface area. It is widely used in industrial and civil heat exchange systems. Its core advantages lie in optimizing fluid dynamics and heat transfer performance through structural innovation.

I. Internally Threaded Metal Finned Tube & Pipe Structure and Manufacturing Characteristics

-

Base Tube and Fin Design

- The base tube is typically made of seamless steel (carbon steel, stainless steel, or copper alloy), with helical grooves (internal threads) machined on the inner wall and spiral or serrated metal fins wrapped around the outer surface.

- Internal thread depth ranges from 0.5–2.0 mm, with a pitch of 5–20 mm; fin height is 5–20 mm, and fin density is 19–60 fins per inch.

- Manufacturing methods include high-frequency resistance welding, three-roll skew rolling, or laser welding, ensuring metallurgical bonding between fins and the base tube with a joining rate ≥95%.

-

Performance Advantages

- Heat Transfer Efficiency: The internal threads increase turbulence by 30–50%, boosting the heat transfer coefficient 2–5 times compared to smooth tubes, while fins extend the total surface area, improving overall efficiency by 4–7 times.

- Durability: The seamless base tube withstands high pressure (≤10 MPa) and high temperatures (≤800°C), with alloy materials (e.g., BFe10-1-1) extending service life 3 times longer in corrosive environments.

- Anti-Scaling: Turbulent flow inhibits fouling, reducing maintenance costs.

II. Internally Threaded Metal Finned Tube & Pipe Applications

-

Industrial Applications

- Energy & Power: Used in economizers and air preheaters for waste heat recovery, improving efficiency by 40%.

- Chemical & Metallurgical Industries: Applied in high-temperature exhaust cooling and reactor heating, with corrosion-resistant alloys suitable for harsh acidic environments.

- Refrigeration & HVAC: Enhances dry evaporators and heat pump condensers, increasing energy efficiency by 20–35%.

-

Civil Applications

- Building HVAC: Finned tube radiators cover up to 500 m² per unit, with a comprehensive efficiency ratio of .

- Agricultural Facilities: Galvanized finned tubes for greenhouses resist moisture and dust accumulation.

III. Internally Threaded Metal Finned Tube & Pipe Selection and Maintenance Tips

-

Selection Criteria

- Choose base tube material based on operating conditions (copper for refrigeration, stainless steel for high-temperature/corrosive environments).

- Fin arrangement affects flow resistance; staggered layouts can reduce wear by 62%.

-

Maintenance Guidelines

- Regularly clean fin dust to prevent airflow blockage.

- Inspect anti-corrosion coatings in high-humidity environments to extend service life.

The internal threaded metal finned tube achieves high-efficiency heat exchange in compact spaces through structural synergy, with ongoing potential for advancements in composite materials and intelligent control.

dtfinnedtube.com

dtfinnedtube.com